The compound rest holds a secret to improving the resolution of infeed setting on a lathe. This is useful for both turning with a regular cutting tool and when using a tool post grinder.

I think that most lathe uses in Europe and the UK and its old colonies tend to set the compound rest at 0 degs. except when using it for turning tapers. On the other hand I have noticed that many US machinists leave their compound at the angle used for thread cutting, which is just a touch under half the included thread angle. Typically 29 or 29.5 deg for 60 deg thread. Particularly as most hobby machinists only cut threads once in the blue moon it seems rather illogical to leave the compound thread ready.

Is there a better general purpose angle to set the compound rest to most of the time. I think there is and I think that it's 5.7392 deg, that might be a touch fine to set easily so let's say five and three quarters. Basically I set it as close to that as is reasonable by eye. For the non maths phobes that number is arcsin(0.1).

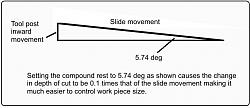

The sketch below shows why I use this angle;

We can see that with that angle the inward feed of the toolpost is 1/10 of the travel of the compound slide. We have therefore increased our setting accuracy by a factor of 10 compared to adjusting the tool post position with the cross slide dial. !0 thou on the compound slide is 1 thou infeed. Likewise 1 thou on the compound is a tenth infeed.

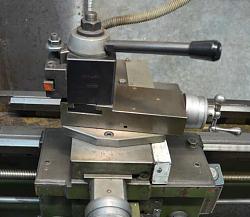

Here is an real example.

I mentioned in another post that I always like to do an error analysis when working with numbers, so how critical is the calculated angle. Roughly the error in infeed is approximately 4 to 5% for 1/4 deg error in setting. That sounds a lot but let's put it in perspective in comparison to using the cross slide.

Say we set the compound at 5.5 deg instead of the target 5.74 deg then if we move the compound by 10 thou aiming for 0.001" at the work piece we will only get 0.000958" or less than 1/2 a tenth error. Try that with the dial on the cross slide. In any case if you can't set the compound angle any better than that you probably couldn't set the infeed any better than 1/4 thou on the cross slide.

I have been careful to talk about tool post movement or infeed and not actual metal removal. When using a lathe tool, advancing the infeed by 1/10 thou with usually not remove 1/10 off the radius, often it will just rub on the surface. Tool sharpness and material properties have important influences on this and is beyond the scope of this post. However, if you are using a tool post grinder then a 1/10 infeed might actually take 1/10 off, when using a fresh wheel.

A side advantage, though often an important one, is that a small angle on the compound rest gives more clearance when you are working close to the tail stock. Many lathes with the compound at 0 deg. restrict the infeed position of the cross slide.

Two views of the offset compound rest close to 5.74 deg.

Thanks for watching.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks