I carried out the following "visual" experiment recently out of curiosity and to answer the question of a friend who happened to drop into my shop. “What are you doing” he asked. “I’m dressing the wheel of my surface grinder” I answered. There followed a number of questions on why I needed to do this, how often I did it etc. My friend seemed to think I was being over-fussy in doing this every time I went to grind. Anyway the results of the experiment were interesting and went some way at least, into allaying my friend’s skepticism. But he still thinks I am being fussy. I did not go into the niceties of truing the wheel with him other than to mention that it is also important to true the wheel beforehand. The question I set out to answer was “Is it so important to dress the wheel every time we use the surface grinder?”

As my friend is unfamiliar with machine shop work and techniques I tried using the analogy of driving a car. The tires are the only point of contact we have with the road when driving. To a great extent, the quality and safety of the drive depends on a good set of tires and balanced wheels. Similarly, when grinding, the interface between the wheel and the work-piece, to a great extent, determines grinding quality. A properly balanced and dressed wheel is vital in order to achieve a good finish. So, to make my point, I grabbed the nearest scrap of metal I had to hand, a block of brass, and endeavored to show why wheel-dressing is so important.

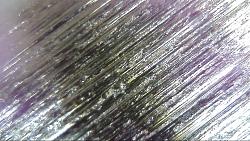

Using a Teslong Digital Microscope (200X magnification), I photographed a piece of brass

1. After machining on the mill

2. After grinding without dressing the wheel

3. After grinding following wheel dressing

4. After grinding having turned the machine off and on again (without dressing the wheel a second time).

While the following cannot be perceived to be as controlled or exact as a scientific experiment, the results are still interesting.

1.

This first photo shows the surface of the material after machining only (magnified 200 times). The machining pattern can clearly be seen as can a couple of pit marks that were not visible to the naked eye. Other than that, nothing unusual.

2. 3.

This combined picture shows the material after grinding without dressing the wheel (on the left) and after grinding following dressing the wheel (on the right). Note the edges of the material were not chamfered before these photographs were taken (the roughness of the edges evident in the photos was not obvious to the naked eye). The difference in the surface finish was clearly visible to the naked eye; the right hand sample appearing much smoother and feeling smoother to the touch. The tiny pitting that appears in the right hand photo was not visible to the naked eye.

The black coloring in the left hand photo represents shadows caused by coarser grinding marks indicating that this sample is not as smooth as the one in the right hand sample. This lesser degree of smoothness was very obvious to the naked eye and to touch by the fingertip. The purple hue in both photos appears to have been something to do with the lighting and did not correlate with anything that was obvious to the naked eye.

4.

The final photo shows the brass after grinding following switching the machine off and switching it on again (no repeat wheel-dressing was done before grinding in this case). The surface finish is poor; somewhere between samples 2. and 3. both visually to the naked eye and to the touch of the fingertip. The black coloring indicates this. Again, the purple hue can be ignored.

Conclusion.

The conclusion to this basic experiment would appear to be two-fold:

Firstly, always dress the wheel before a grinding session. Not only will it sharpen the abrasive elements of the wheel but will also remove any build-up of crud on the wheel that would result in a poorer than optimum finish.

Secondly, do not switch off the machine after dressing but go straight into the grinding work as switching off and on throws the wheel ever so slightly out of balance, resulting in a less than optimum finish. It also follows that the machine should not be switched off and on again during the grinding session lest the wheel be thrown off balance.

Any comments or contributions to this conversation would be welcome.

My friend, by the way, is still perplexed as to why anyone could be so fastidious about their work. He is a hammer-and-nail man, I think.

Happy machining folks!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks