Thank you for such a quick response. Having seen the range of your builds, this is a great way to start.

What is your approximate budget?

Price of this brake is 30% less compared to any apron brake located over an extended period of time, and not too far away. So, the budget was set more by the market than a specific amount. Since standard material is 48", my logic was brake should be in range equal to shear size.

How thick of material are you looking to bend? How wide?

I like 16 gauge for projects I have in the wings. As above, 48" is common width, can be loaded, transported and manipulated alone. First few jobs are wireway brackets, drill bit shelves, toolbox carcasses.

Do you need a press brake (fingers that push straight down into grooved bottom tooling) or will a folding table style work?

Until shop has electrical power a press brake is out. My project designs have simple corners, seams and hems, X'ed or quilted panels; no offsets, large radii, goosenecks or such nonsense.

On the shear, what are you trying to accomplish? I have a 36" foot stomper that I rarely use, instead use my electric hand shears or electric nibbler. Shears are good for long straight cuts, and making bigger sheets into smaller ones that are more manageable to handle.

I've used powered hand-held nibblers and shears, but my plain functional designs are without contours. A foot shear is ideal, with front and rear gauges, again

no electricity yet!

Are you looking to do some volume parts or just one-offs?

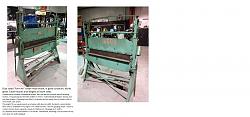

This particular brake [photo] I can front or back gauge too; for repeatability/ low volume.

Brief initial contact with seller started today! Best part, brake is rated 14 ga full width, a good capacity margin. Even good equipment, when they say so-and- so is the capacity, they mean it, not just in clamping but counterweights etc.

Initial sheet work area will be brake, shear, spotweld, an ironworker and punch press later on. Already have Roper bench punch, 5 ton, that I built a fixturing table for. Also have narrow bench bender with a greatly extended stop bar, a modified HF Compact Bender, and slip roll for wire.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks