Hydrostatic transmissions are used in a variety of riding mowers and other landscaping equipment. The operating principle can be a bit difficult to understand, but in reality is quite simple. An internet search will explain the operating principle of the transmission. Basically it consists of a hydraulic pump driven by the motor of the mower. Oil from this pump drives a hydraulic motor connected to the wheels, sometimes through a differential. Many of these transmissions use a cylindrical pump and motor that are nearly identical. A good Youtube animation shows the principle.

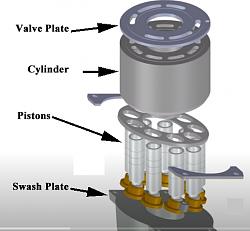

The system uses two tilted plates, called "swash plates" to move pistons up and down in a rotating cylinder that looks like it could be part of a six-shooter pistol. One swash plate has a fixed angle, and the other one has an adjustable angle. By changing the tilt of this swash plate, the out speed of rotation can be changed, and even reversed, producing a continuously variable reversible transmission. There are two valve plates that direct oil from the pump pistons to the motor pistons. These valve plates rotate against the end of the steel cylinder, and are usually made of brass or another dissimilar metal to prevent galling. Sometimes a grain of sand or other debris gets lodged in the valve area, and can scratch the valve soft brass surface of the valve plate, causing an oil leak that will impair or prevent proper motion. It may be possible to repair the scratch by use of fine grit wet or dry sandpaper on a flat surface (granite block is ideal) to polish out the scratch. If the scratches are deeper, a skim cut on a lathe may be required, but be careful to remove only as much as needed since sometimes the brass layer is thin.

Typical Transmission from Toro Mower

Hydrostatic Motor or Pump

Valve Assembly

Scoring on valve plate

Valve Plate after scratch removed

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks