Hey

I'm kinda upset cause I can't find a simple way to use my excavator hydraulic systems to make a sheet metal bender! I want one and I want everyone to show me how to do this!

Don't make me have to wait for details or ideas either.

I mean it

.

Hi Ball baby - welcome to HomemadeTools.net

Interesting build. Go ahead and try making a new discussion in our Tools in Progress subforum, and I'm sure you can get some good ideas: Tools in Progress

New plans added on 11/20: Click here for 2,589 plans for homemade tools.

Hi Ball baby,

Welcome!

I'm interested in the answer to your question, too. If there's a way to do it, someone here will set you on the right path.

What are you planning to make with the new bender?

Ken

Ball baby (Aug 10, 2016)

Ball baby (Aug 10, 2016)

Well?

What responses or ideas have occurred for this?

That amount of power will need fine control to avoid damage to apron and bed. That will dictate gauge and potential widths for a design. Will also require substantial trunnions, but eccentric cage pillow blocks that you can align will kick this in gear. Parallel is KEY to a brake, in both planes. What material do you intend forming?

Sincerely,

Toolmaker51

...we'll learn more by wandering than searching...

Ball baby (Aug 10, 2016)

To start off with from the way Your first post was worded it may not be well received by some,

However you didnot mention anything about the size or gauge of the material you desire to build this sheet-metal bender for

nor didyou state the size and breakout force of your excavator for all anyone here knows you may own a little mini excavator like a Kobelco 004 with only a few hundred pounds of force or a huge Kamatsu P600 with hundreds of tons of digging force.

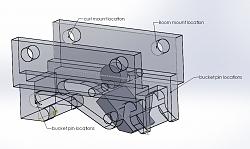

Be that as it mayif you are wanting to use the bucket curl function as means to operate your bender the first thing you would need would be a means of attachment this can be done by the use of a quick tool change assembly similar the the picture below

If you already have one of these it is a simple task to design the bender around that allowing the excavator to replace your hands and arms

just add some pin locations that would resemble those of the bucket to something like this

If you are wanting to use the auxiliary hydraulics function then simply design your bender around the amount of pressure and flow that you have

Last edited by Frank S; Aug 8, 2016 at 02:03 AM.

Never try to tell me it can't be done

When I have to paint I use KBS products

Ball baby (Aug 10, 2016), Jon (Aug 8, 2016), Paul Jones (Aug 8, 2016), Toolmaker51 (Aug 11, 2016)

Thanks everyone best response I've seen on newbie entry.

Sorry if I sounded like a ball baby at first.

My excavator is a Dawoo 140 and has a large blade thumb and 24' reach. I'd like ideas on my plan to build a bolt on bender to the blade and use the bucket for the bending force. Franks ideas are very helpful and run in parallel with my idea. I have not started the build or design just saw it in my mind while running the excavator see how the bucket force can be directed over the blade or the blade raised and lowered ad another way to operate the bending process. Like be able to bend 10 guage steel as this can curl and snap 18 " trees

Fun to be here. Just wonder why I didn't get a email notice that I had responses.

Unfortunately the available data on the internet about your machine do not give me the 1 piece of info I was looking for unless they are calling it the Bucket Digging Force this sounds like the overall force the bucket can exert on the teeth during the curl function the force of 24,471 lbs is considerable for a build such as you are contemplating which can be multiplied greatly by having a long swing arm on the break. should you go with a folding box finger break similar to the one in my picture

for a build such as a press break design you will find that the machine would be sadly lacking in both power and finite control unless you incorporated a cam like action above the punch beam

the blade in either case is going to be able to do little more than serve as a platform to mount the metal bender on.

Additionally you will find that trying to position the work in the break is going to be tedious possibly requiring 3 persons to operate this. 2 on the ground to place and position the work piece and 1 in the cab at the controls making it a very dangerous function.

bending metal on a machine like this will be like trying to put eggs in a carton without breaking them using the thumb and the bucket.

That being said the hydraulics of the excavator are impressive with 4694 norm &4978 PSI boost @ 30.12 GPM

You could always use the hydraulics VIA a remote to power a rather large standalone break of any size.

I think that if it were me and I wanted to build something that I could use my excavator as the brute strength to bend metal with and had a helper or 2 I would build a finger folding break that I could hang over the blade with quick tool change attachment on the stick then use the auxiliary function that controls the thumb to close the top clamp then use the curl and stick movement to power the folding beam.

Just my observations. and I don't mind offering or expanding on any build ideas.

Last edited by Frank S; Aug 11, 2016 at 01:55 AM.

Never try to tell me it can't be done

When I have to paint I use KBS products

Toolmaker51 (Aug 11, 2016)

There are currently 1 users browsing this thread. (0 members and 1 guests)

Bookmarks