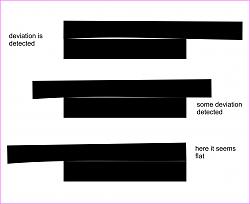

I have tryed the 3 plates method described by J. Whitworth to make flat surfaces from scratch, i.e., without the help of any other flat surface to use as a reference. Awesome and supertedious. Since there is no much online that give information on how to actually carry out this process, I have shared my experiment in this video, with the hope it will be interesting and helpful to others.

Cheers.

This is the link to the video:

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks