The operating levers on garden hose ball valves found in consumer outlets are way too short.

I have reasonably strong hands and fingers but I about canít turn this SOB without pliers when itís new. My first attempt at modification didnít work. Under that rubber cover is a skimpy metal part that looks like brass but in fact is brass-plated pot metal. Pot metal is OK if thereís enough of it, but the people who design these things keep removing metal until it no longer works, then add back three or four atoms worth and start production. When I tried to fasten a forked extension on with a machine screw, the valve lever broke. I said a bad word. (Shame!)

Ah, but I have a machine shop. Iíll not be defeated by a $7 hose valve! (Used to be $2.50)

I made a mandrel that resembles the actuating stem of the ball. That was easy peasy, 5 minutes at the lathe and 5 minutes at the mill. Quick Ďn dirty. It only needed to work once.

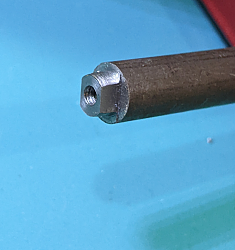

I put what was left of the actuating thing on the mandrel, chucked it up in the lathe and machined off pot metal until all that was left was a round cylinder above the part with the radially protuberant tit that limits rotation to 90 degrees. Then I machined a brass cap from a bit of 3/8Ē brass bar stock, making a lathe-bored cavity about 0.0015Ē smaller than the pot metal valve part. I silver-brazed a bit of ľĒ rod to the brass cap to serve as an operating lever, and then I pressed them together in the Kurt mill vise that can exert at least a ton of force while keeping faces parallel. The part in the middle looks like brass but it isnít; itís brass-plated pot metal.

I dabbed a bit of Loctite 609 (the green stuff) on it before assembly but I doubt that itíll make any difference. It probably all got squeezed out.

I reassembled it to the valve with a stainless M3 x 0.5 mm metric button-head machine screw and voila: ready to go to work hosing off the fish-cleaning table at da laaaake. Itís very easy to operate without getting hurty fingers. I hate getting hurty fingers.

The joint is just a butt joint. I made a concave curved face on the end of the rod with a ĹĒ end mill, butted the brass parts together at the bench and silver-brazed them. The rod would bend before the joint would fail. A good silver-brazed joint can be stronger than the parent metal. And besides, ya canít weld brass but silver brazing works very well.

These garden hose ball valves are not forever. This isnít the first one Iíve modified, or the second. They last for a few years and then they start to leak so need to be replaced.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks