I hope to inspire people or give some ideas by making these videos of my home-projects. Thanks for taking your time, I hope you enjoyed...

asterix (Jan 20, 2021), blkadder (Jan 19, 2021), Jon (Jan 20, 2021), NortonDommi (Jan 20, 2021), sacco1 (Jan 24, 2021)

Please mount your camera on a stable base and bring the work to the field of view.

The constant rapid camera motion impairs viewing of useful content and is nauseating.

I think I saw the method of transmitting torque to the spindle was via the squared hollow stub shaft. That stub shaft was installed with a light interference fit to the main spindle. Is that correct? You think that interface will hold up to substantial milling or drilling? Time for some additional Engineering.

Thanks engineer steve! We've added your Mill Spindle to our Milling category,

as well as to your builder page: engineer steve's Homemade Tools. Your receipt:

New plans added on 12/16/2024: Click here for 2,633 plans for homemade tools.

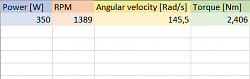

Thanks, I am definitely working on the camera work. About the square shaft: I have done a 3D CAD-simulation with torque applied to the shaft, up to 30 Nm of torque the shaft shows no problems at all. I calculated the (350 Watts)motor torque to be 2,4Nm, nominal. A 1:3 transmision results in 7,2Nm at the shaft, not including startup torque (which will be low as the milling cutter normally doesn't touch the work on startup). Conclusion: a safety factor of aproximately 4. The included image shows the simulation with 30Nm of torque on the shaft.

sask man (Jan 20, 2021)

"I think I saw the method of transmitting torque to the spindle was via the squared hollow stub shaft. That stub shaft was installed with a light interference fit to the main spindle. Is that correct? You think that interface will hold up to substantial milling or drilling?" I was thinking the same but the answer is a good one.

Last edited by NortonDommi; Jan 20, 2021 at 05:45 PM. Reason: Add information.

The issue is not whether or not the square shaft will handle the torque. The issue is that the light interference fit between the lower quill and the upper stub (square) shaft will not. Your FEA is looking at the wrong area. The problem will become obvious once you attempt to drill 1/2" diameter hole through 1/2" thick steel.

I already found out that this 350W drill press is not able to drill holes that large without pilotdrilling. But in case I want to swap motors (to max 500W) I will make sure to change the square drive to have a shrinkfit or use loctite to secure it.

Thanks for your comment, I understand your concerns and will make sure to keep an eye on that part!

There are currently 1 users browsing this thread. (0 members and 1 guests)

Bookmarks