Hi All

I had an interesting job come in to the workshop that needed to be broached/slotted.

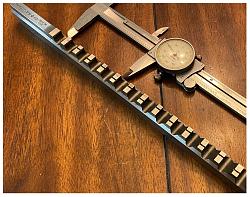

These photos below show the finished component, setup and tool.

To cut the slots I decided to make a slotting tool from silver steel which was hardened and tempered. This was then attach to a mild steel tool holder.

The photos show the completed slotting tool and finished component.

To slot the component the quill of the milling machine is simply raised up and down without the spindle rotating. Taking very small/light cuts 0.02mm (0.001”) per/pass until the required depth is achieved.

To index the component it was placed into a indexing head and the mill spindle placed over centrally, each slot is then slotted to the required depth and the width of the tool maintains the width tolerance.

Finished slotted component cut to required tolerance +\- 0.05mm (0.002”)

With the component made from aluminium this did make the process a lot easier. However this method works very well on all materials but depending on the material to be cut the cut/pass my need to be reduced and cutting oil or coolant helps the cutting.

Hope this will be of interest and thank you for viewing

The Home Engineer

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks