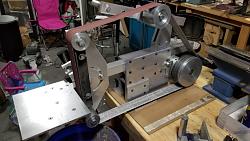

About a year ago I built a 2x72 belt grinder. It is made almost entirely from aluminum scraps that I sourced at a salvage yard. It is powered by a 90vdc treadmill motor and controlled with a DC drive. The wheels were all turned from blanks that I cast from my aluminum foundry. One feature that I incorporated into my design that I have not seen on others is a reversible tool arm. One side has a flat platen and the other holds a small wheel attachment.

This is now my go to tool. If you have been thinking about making or buy a 2x72 grinder, then do it. These things chew through metal at a rate I did not image. Shaping metals has become so much easier.

These are pictures of the roughly casted billet and turning it down to make a roller.

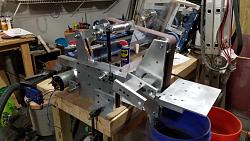

These are picture where I made the tool arm and platen. I don't have a rotary table so I used a router to cut the radius for tilting the platen.

These are picture of the body mocked up and partially assembled.

This is turning the large wheel that added width to the pulley on the treadmill motor. I didnt want to make an entire wheel so i just added on to what was already on the motor.

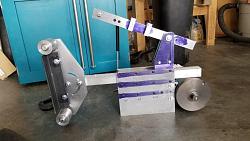

This is the bracket that hold the small roller for the small wheel attachment.

These are pictures of the completed grinder.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks