I had to scroll back to see why you were talking about Leon. I knew of Leon, in our previous discussion I was just indicating that I was not familiar with his work although I knew of him.

I looked into many ways to measure air flow for the bench. Most benches use an orifice plate but the flow coefficients are low, 50 to 60%. I used a venturi in place of an orifice plate, coeff around 96 to 98%, so I only need a vacumn source of roughly 1/2 that I would with the orifice. Combined with electronic differential pressure transducers it is very accurate and highly repeatable. Most/all orifice machines have to change out plates at different flow rates, even when doing a single test over a range of valve openings on the same port. With my venturi I have to change out nothing. Testing is very quick. My software averages 100 readings over a set period (usually 5 secs). All I have to do is set the valve lift, push a button, wait 5 secs and repeat for as many steps as I want. My software does the rest.

I don't see any price or functional reason to use a weather anemometer over what I have.

Click for full size images.

Ventururi with temp sensor attached. See my old post on ruggedized temp sensors.

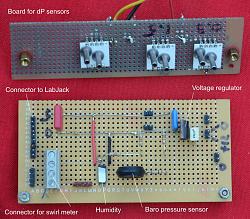

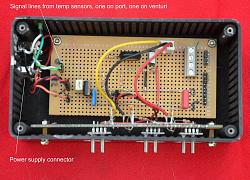

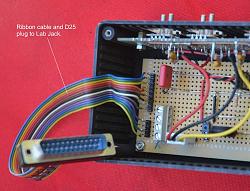

Some pix of the black box and DP sensors. There are humidity, baro and temp on the board as well as a temp sensor on the venturi and port. These parameters allow the results to be compensated for different atmospheric conditions. I obtain indistinguishable results from testing at 0 deg when I lived in NH, USA and testing at 30 deg here in Spain. My workshop is always 30 deg in summer.

I use a floating plenum pressure as Vizard has as well. However, I realised when I made my first bench a long time back that even without electronic sensors you could make accurate manometers from clear plastic tube and coloured water to actually measure flow. That is unlike Vizard's first efforts where he only got a "better or worse" indication. I had real flow numbers from the outset.

As you suggest I do use a motor from the biggest shop vac that I could find on a trip to the US. I extracted the motor which was light enough for a suitcase and left the rest behind.

Anyway I'll leave more on the flow bench subject until I make a full post about that. Maybe this discussion will bring it to the top of my list to document. I was intending on doing something on an LVT that I made for my shock dyno or some modifications to put my bead blaster on steroids.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks