I started making mechanical things around 1960 when I was 16, it was electronic things before that. One of the tools that I made early on was a small horizontal milling machine. I remember using it on some jobs but for the life of me, nearly 60 years later, I can't remember why I made it. A vertical mill would have been more useful. such is the foolishness of youth I guess. I made wooden patterns and had the pieces cast at an iron foundry, most of the machining was done on my Myford lathe. The amount of stuff that has been made on Myfords across the world is staggering. A year or so later I bought a regular size horizontal machine at auction which I converted to a vertical machine by making a head from welded steel plate.

This is the only picture that I have of my workshop from the early 1960s.

It was in a wooden box previously used by furniture shippers, and was very crowded. Unfortunately the little homemade mill is not visible, it was hiding behind the one converted to vertical. The subject of the photo was really an engine dynamometer that I built from a torque convertor, not the machine tools.

I was living in Australia then but I moved to England in 1971. I was limited on what I could ship over but the little mill was small enough to take. I never did get it up and running in England, I had no use for it basically. Then in the late 1980s I moved to Spain and the little mill trailed along too. Until a few months ago it just languished on the floor of my workshop here, talking up space and getting covered in dust and anything else that fell on it.

Here it is on the floor next to the filing cabinet.

It stayed there until a few months ago when I got the idea that I could turn it into a small surface grinder, maybe not high precision but useful nonetheless. When I first got it up on a bench it looked in a pretty sorry state, rusty etc. I wasn't very hopeful. Here are a couple of photos as it was.

However, it was actually in pretty good nick. What looked at first sight to be rust etc. just turned out to be decades worth of grime congealed on the protective grease that I covered it in back in 1971 in preparation for its long sea voyage. The following is a succession of photos during the new build up after cleaning. I think that the sequence shows the construction pretty well, without much explanation. Before assembly I thought that it would be a good idea to check everything for flatness and squareness so that with better machinery now I could correct any original errors. Much to my surprise there was nothing that needed re-machining.

Finally mocked up to see how it might look as a surface grinder.

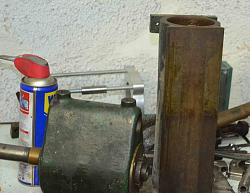

I haven't actually finished it off or tested it as a surface grinder because it occurred to me that if I swapped the head with my lathe tool post grinder, and added a spin indexer I could have a very capable Tool and Cutter grinder. I did that and it works a treat, but that will have to be the subject of another post. In the meantime here is a teaser.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks