Albert,

I have at times past tried Alibre and Fusion as you suggest but the simple truth is that I do not need much in the way of drawings and I regret any time spent that is not directly making what I want. When I was younger, way before desktop CAD I used to do proper engineering drawings for my own stuff but at work I always had drawing offices to do the drawings for me, it was considered a waste of an engineer's time to spend it drawing. In the 1970s I had my own business making racing motorcycle chassis, so it was back to the drawing board but I guess that with increased experience I needed no more than basic layouts to check geometry. Then when desktop CAD came along I was having a break from making stuff so I never got into CAD. Now I only make stuff for myself and I rarely even need to make rough sketches, only for complex things like complete engines. That is not to say that I am not accurate or that I am careless or slap-happy. It is just that I do not need drawings to achieve the required result. I am very careful and usually think long and hard about any design but that is a mental activity without the need for drawings. I have never had problems with parts not fitting together nor creating interference. I am able to visualise 3D shapes just as vividly as a CAD jockey does on a screen.

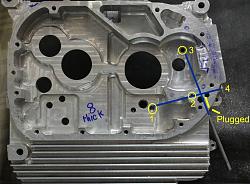

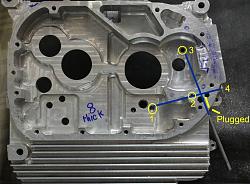

I have a CNC Bridgeport and so you would think that CAD would be essential but my stuff is either 2 or 2.5D and for simple stuff I use the MDI interface, for not so simple stuff I hand write G-code and for more complex stuff I write dedicated software that outputs the G-code. Today for example I made what I hope will be an improved design of gun for my bead blaster. It required linear and circular interpolation, boring and thread milling. That was all done via MDI and the whole job was far quicker than if I had taken the CAD/CAM route. Here is a work-in-progress example that had some roughing done manually and the CNC work was from hand coded G-code.

There are times though when the lack of drawings or schematics does come home to bite me. Mainly with electronic stuff, if I need to return to something after a time away from it my ageing memory lets me down. Fortunately, most such projects these days are a mixture of electronic and software, and I can generally work out the hardware design by reading the software.

Different stroke for different folks, I guess.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks