Hi,

I already showed different approaches to mount a rotary tool on the lathe, a Dremel mount or a Drill mount or here and the smaller chuck version here.

In that quest, I think I have found the ultimate solution, which fixes all the drawbacks of the different solutions above.

1st quality, there is no or very small run-out, second it features an ER11 chuck which allows for a wide range of bit diameters (ok, up to 7mm).

In addition it is quite powerfull (400W) and can spin from 0 to 12000 rpm, with good torque even at low speed.

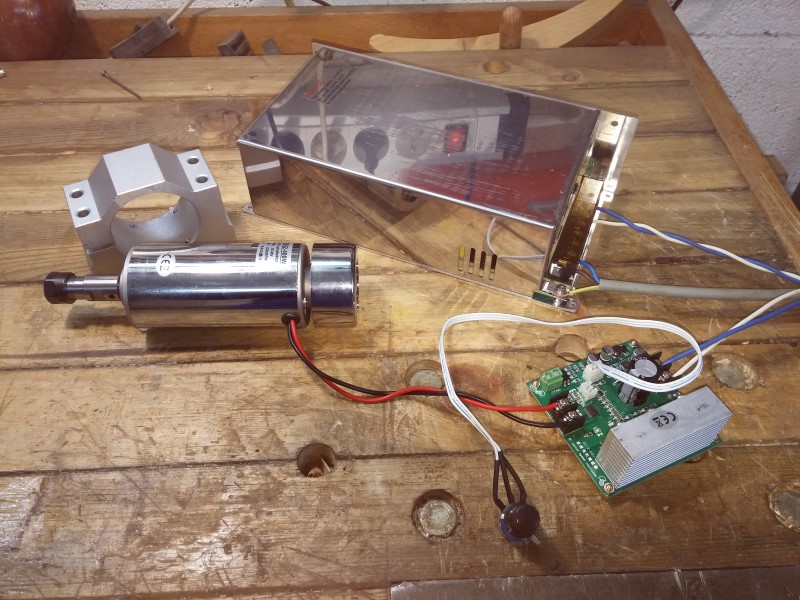

This spindle is actually a CNC spindle sold on the well known Chinese platforms. I purchased mine on eBay, and I must say that I am so far very happy for the value and quality.

The kit contains the spindle, air cooled, the power supply, 48V / 480W (quite usefull by itself) , a PWM controller board with a potentiometer to regulate the speed, and a clamp designed to hold the body of the spindle with 4 screws.

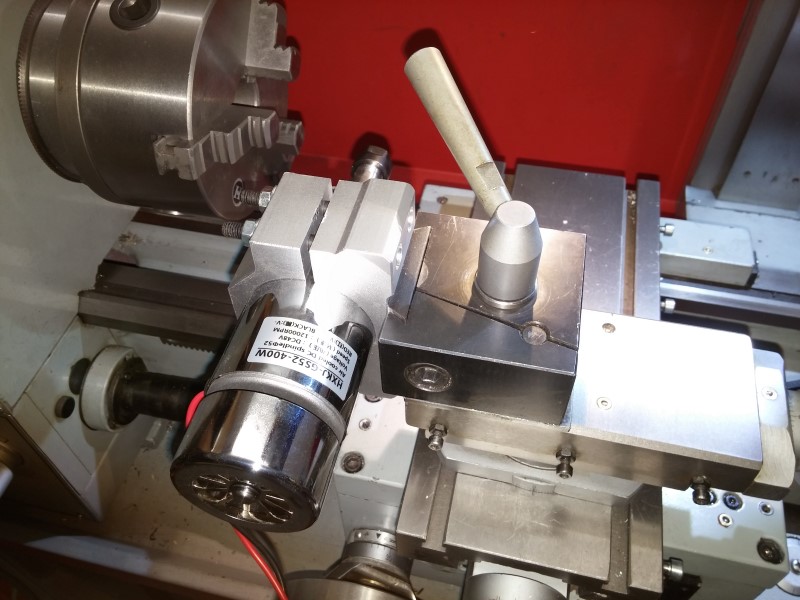

My plan is to install that spindle in the QCTP of my metal lathe.

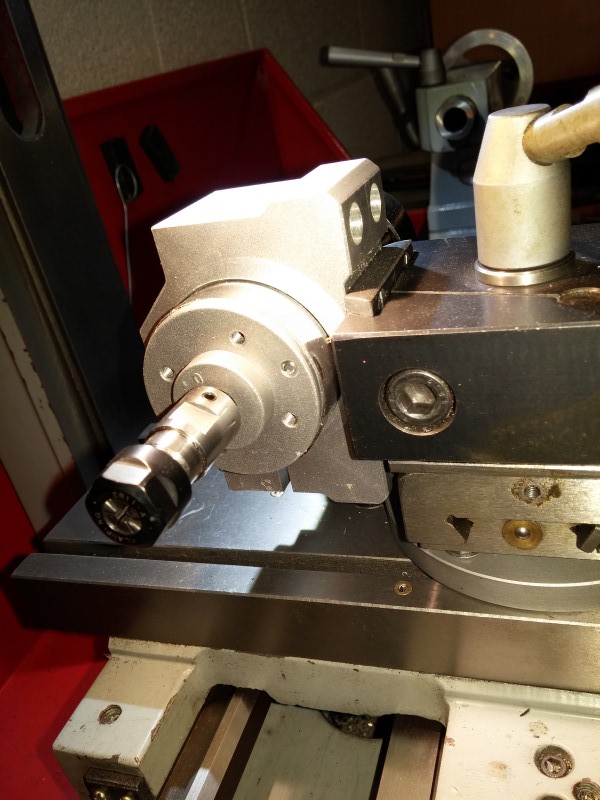

I had to slightly modify the aluminum clamp, milling flat the bottom of the sole, and then I screwed this steel dovetailed plate, in order to fit the QCTP socket.

Here is how looks the spindle tool ready for mounting in the QCTP.

Then I had to pack all the components and mainly isolate the power supply and control board.

I had the idea of making a box that would have a double purpose : enclose all the component AND tidying up all the parts for transport and storage.

Here is the box finished and closed

And on the left part, you can see the parts and cords in it.

I can attach the box to the lathe with two simple wire hooks

Ready to use the tool

The spindle tool mounted in axial position

The dovetail allows for height adjustment. I think I will improve it with a screw mechanism for fine adjustment.

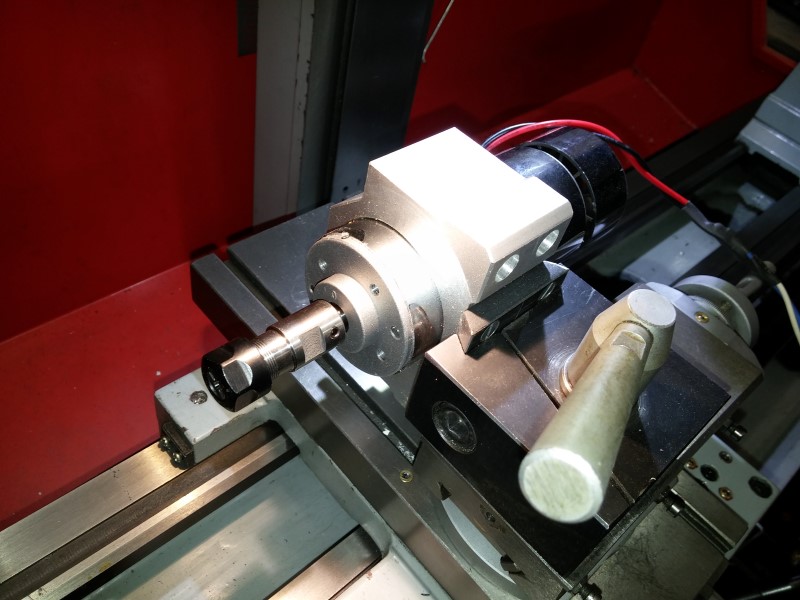

The spindle tool mounted in transverse position

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks