I picked up one of the Harbor Freight belt sanders (60543) a couple of years ago for $29 with a coupon. It's been ok and have done some other mods to the wheels by crowning them a bit better and truing them up on the mini. I use it quite a bit and have a good selection and various types of belts for it now from 60G to a leather strop. But the handle for the table tilt has been a pain since the beginning. The screw for the quick release spring tension adjust was bungied from the beginning and it never locked the table very well. I must have broken the (1-800-bad plastic) handle 4 or 5 times. Kept gluing it with Loctite gel ca glue but finally it exploded beyond repair.

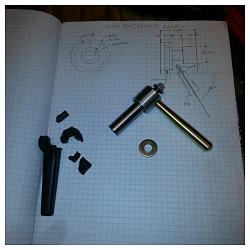

I mic'd what was left from the exploded handle and sketch out the number. The housing is a piece of 1" AL RB turned down to .875 then bore through .25 and counter bored on both ends to the numbers on my sketch book (zoom in). The critical one was the .715 for the splined collet I salvaged from the broken handle. Because it wasn't very round I bored it until I could just slip in the collet and never did mic the final dim...but it was a nice fit. Turned out it had 4 dimples in it so I could use as 4-40 set screw to lock it in place (can't see it in the pics but its opposite the handle and just eyeballed the location).

I really wanted the handle to come off at 30º but alas with a HFT Drill press it was not possible even with a center drill, so I punted and put it at a much shallower angle (?) that I could drill at. Tapped it 1/4-28 mainly because I only had about 3-4 threads of engagement at 28TPI. (The handle can't penetrate into the spring area because it will interfere with the spring release action.)

Next I started the handle with a small piece of that old ground rod I got years ago (Got a Lot of Mileage from that so far). Turned down for the threaded end and used a die to thread it. Then put the taper (~3º included) on it and used a graver to create the round end. I ended up having to trim some of the threads off so it wouldn't interfere with the spring....better long than short!

The final operations were re-taping the end of the main splined shaft 10-32. Think it was 4mm before (too bungied to tell) but got some nice clean threads. Then used a piece of ~.50L X 1/4" stainless tubing from the bin for a sleeve instead of making an whole new shoulder screw. The ID of the tubing needed a bit of a hair cut to slip fit the SS 10-32 SHCS I had in the bin. I ended up chucking up the splined shaft in the mini and removed all the blacking (Hides Beer can material) and refacing the end that contacts the table slot. The brass washer was a left over in my washer bin from my Green Machine fix for my Brother. Also put a bit of 242 Loctite on the handle threads to hold it from coming out.

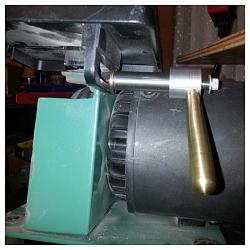

It came out well in the end, only took a few hours. Now with just a 10-15º movement of the handle it locks the table strong with a smooth and quick action. Boom Done...one more project off the list and another silk purse on a sow's ear.

This was all done on the fly and you can zoom in to see some of the numbers in my sketch (chicken scratches). Hope this helps others with these kinds of problems with cheap and cheerful priced tools that we can make better with scraps and some fun tinkering. ~PJ

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks