Hi, all!

I'm (also) obsessed with making a few different (1, .7 & .5) module hobs for cutting involute gears, and have a few question:.

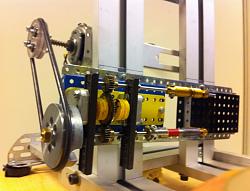

Pic from Ivan Law's book "Gears and gear cutting":

Background:

To even grind the tool's helix angle and .73 mm front flat tip* of the turning tool as per the right pic above,

I first need to design the entire hob - Right?

Mod 1 hob formula for simplicity:

OD of hob: 25 mm,

DOC: 2,41 (Addendum 1 mm + Dedendum 1,25 mm & Hob root clearance 0,16 mm = 2,41, correct?),

so at PI mm worm pitch (as it's Mod 1) and a 22,59 mm average dia of "tread",

that would give med the helix angle: tan a = 1/22,59, or 2,53 degrees - right?

If I'm correct above, it would be pretty straightforward to grind the tool by tilting its holder an extra 2,5 degs,

but then checking its geometry in (say) a Shadowgraph it has to be held at 2,5 degs as in the pic above,

and not be twisted so as to keep its top edge horizontal, i. e. not kept flat, as in a 40 deg angle gage...

*A theoretially "pure", sharply pointed 40 deg 1 MOD cutting tool would have a 3,41 mm DOC.

But this, with its 0,73 mm tip width (thus 1 mm ground off the sharp tip) should then only have a 2,41 DOC,

to generate a generous enough "non-topping" hob.

Any ideas/ corrections positively welcome!

Johan

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks