Hello guys, after having posted my latest video on the spindle for my lathe I had a guy who pointed out that for him the thickness of the collar clamps that hold the spindle in the headstock are too thin and would break catastrophically when in use with off-center parts held in the jaws of the chuck. I did some calculations when I designed the part and I considered this problem, however he put me a doubt and I re-checked everything again because, you know, "safety is the number one priaoairhity" as CreazyRussianHacker would have said

So, I post here my review of this thing to ask for opinions and let you catch any flaw in my calculations, if any.

To see the video, go to my YT channel (be sure to click the "videos" section.

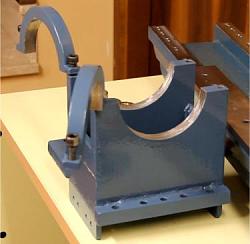

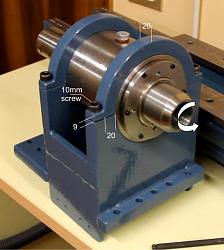

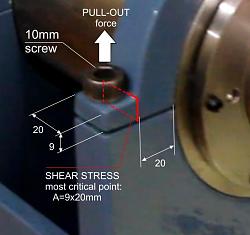

Here some pictures of the headstock and the spindle, with dimensions:

The collet clamps are made out by cutting with a plasma torch the part from a single 20mm sheet of mild steel. There are no weldings, it is a monolitic piece of steel.

My calculations was the following:

- static shear stress, for mild steel is about 240MPa (approx. 60% of the UTS), on a area of 9x20mm is 180sqmm (the smallest area, hence the most critical point, of one side of the collet, see last figure) giving a 240 * 180 = 43200N (or 4400 Kg of equivalent force, 9700lbs) of force required to make the metal yield.

- the bolts however should be the most critical point, as it has a much smaller area and for the M10 screw have an ultimate minimum load of 24400N (conservatively picked for mild steel cold threaded) which has an equivalent force of 2487Kg (5483lbs).

(i.e. see here: https://www.engineeringtoolbox.com/m...ds-d_2026.html)

So to tear apart one side of a clamp an equivalent force of more than 2400Kg should be exerted.

The real problem however lies on the fatigue limit that could lead to a failure after a given number of cycles.

In fact, suppose a part is kept in the jaws of the chuck and in rotation, this will generate an oscillating force against the clamps, with an average force of zero, that could cause a failure due to fatigue.

This could be particularly true in the case a micro-crack or defect in the metal act as a trigger to start a major crack that grows and propagates deeply into the metal at each load cycle.

Reading the literature on the topic I've found that typical mild steel with no micro-cracks or defects fails after a progressively higher number of cycles as the cyclic load is reduced, up to a point where even after a huge number of light load cycles it would never fail.

This is point is at a ratio of about 1/3 to 1/4 of the ultimate shear stress.

Using a safety ratio of 1/5 with my data above would lead to a maximum force of 4880N or equivalent force of 497Kg (1096lbs).

This means that the case of an unbalanced part in rotation kept by the jaws of the chuck would cause a centrifugal force of max 497Kg.

So that was my final assessment: Since the whole lathe would end up weighing around 200Kg (yes, it is a mini lathe despite the apparence of the spindle that is large only because I wanted to have a relatively larger hollow shaft), if a part, with a certain mass and spinning at a given speed, were to make an equivalent centrifugal force larger than 200Kg (250Kg if we add a generous weight of the bench) the whole lathe and bench would fly away well before having the risk of failure of the clamps.

I have discussed the thing with a friend who happens to be a mechanical engineer and he gave me a confirmation of my assesment, yet I shared this with you to hear other's point of view that might spot overlooked mistakes.

So, any thought is welcome. Thank you.

Cheers, Claudio.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks