Friends,

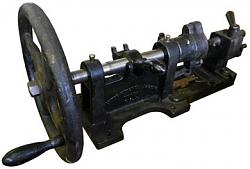

A few months ago someone was selling a bunch of single purpose hand turned lathes intended to be used on PT Boats during WWII but the war ended before they got distributed.

At any rate, it got me to thinking.

I would like to have a small bench mounted and hand turned lathe. I would like for it to have auto feed at a reasonably slow pace so as I turned it with one hand it would reduce the diameter of the workpiece with good clean cuts. If it only takes .003"—.005" per cut, I can live with that.

It would have only two necessary tasks—to turn cylinders of Chrome-Moly down to the desired diameter to become Cylinders or Barrels on Scratch-built Revolvers. On my design the Barrel doesn't need to be threaded and any other necessary threads can be done with taps and dies.

It isn't essential but turning tapers would be a plus as would having an auto-feed for facing off work pieces.

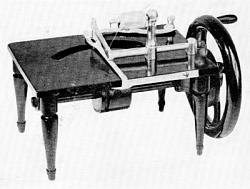

I have a picture of an old Wilson Hand Turned Sewing Machine that looks much like I envision. I intend to include the Wilson Patent because it might be of interest to some. There is also a Photo of some heavy-duty cast iron flywheels that were available back then, but may not be around now.

I'd like to have some input as to how this could be put together using plate metal, ACME Thread Rod and Nuts; perhaps using barbell plates for flywheels and requiring a minimum of welding.

I'd appreciate any input.

The patent didn't want to attach. I guess that it is too big. It is Patent Number is 7776 Patented Nov 12, 1850.

Saxon Violence

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks