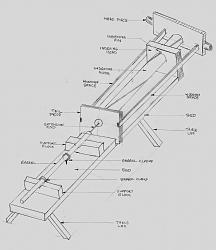

I built this little tapper for the sole purpose of tapping a hole at 90 deg. Everyone knows how easy it is to tap a hole by eye and be a little out of perpendicular, I don't do a lot of hand tapping but this will take the guess work out , Most of the holes I tap (about 90%) are drilled and tapped in the mill or lathe.

I put a 0-3/8" Jacobs chuck on the spindle to accommodate taps up to 3/8" but I seriously doubt I tap anything larger than a #10, In fact I built it for smaller taps specifically, You can also put a countersink in the chuck and chamfer holes, you can put reamers in as well.

There are 3 rows of .257" holes for inserting 1/4" dowel pins to rest the work against while tapping, There is a 7/16" hole in the center for chips to exit and tap clearance and two 1/4" counter bored holes for mounting purposes.

Click here to purchase a set of these plans http://www.homemadetools.net/forum/t...-machine-51083

Below are some photos

Thanks for looking and happy machining

Doug

Above photo shows all the parts machined and ready for assembly

Above photo shows the column attached to the base by means of a 1/2"-13 SHCS, The base is fabricated from a piece 1" X 5" X 9" 1018 CRS which after I precision ground, The column was made from a piece of 1" O.D. 303 stainless steel.

Above photo shows the yoke mounted on the column with it's locking knob in place. The yoke was made from a piece of 1 3/4" O.D.X 7/8" I.D. D.O.M. tubing 2 1/4" long, this piece fits over the column, the other piece which supports the spindle was made from a piece of 1 1/4" O.D. CRS 2 1/2" long, the flat piece was made from a piece of 1/2" X 2" X 2 1/2" CRS

Above photo shows the spindle in the yoke with the Jacobs chuck and it's locking knob, Both locking knobs have a piece of 3/16" round delrin under them to prevent scoring the shafts, The spindle was made from a piece of 5/8" O.D. 303 stainless steel

Above photo shows the handle fully assembled and installed on the spindle, There is custom made acorn nut on top of the handle along with two custom made flat washers, one washer under the handle and one under the acorn nut, the two washers and acorn nut have been blackened

Above photo shows the machine fully assembled with a piece of material drilled and ready for tapping resting against a dowel pin

Above photo shows another view of the machine ready to tap

Click here to purchase a set of these plans http://www.homemadetools.net/forum/t...-machine-51083

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

HomemadeTools.Net

HomemadeTools.Net

Bookmarks