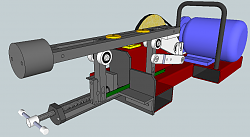

Yet another hacksaw machine, this one is built from mostly second hand parts about two years ago.

Capacity is 4 inch square, stroke is 3 inches and speed is 125 cutting strokes per min.

I prefer the linear motion type instead of the rocking frame variety as it gives a better motion to the blade, so this design is dictated by the materials I had available and the need to make it using only a lathe and pillar drill.

The traditional method is to use hexagon bar but I already had some ¾ square bar available some 4 X 2 inch box channel and some 10mm alloy plate so a way of using all this was devised.

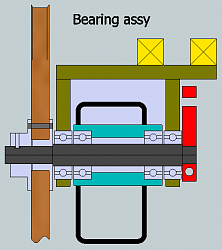

The motor is from an old cement mixer as is the Poly V drive belt, there are 10 ball races in total (all pre used but serviceable for this).

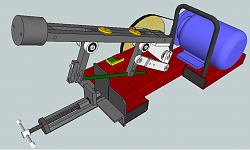

As is oblivious from the pics the blade frame rides under the guide arms on 4 races which take all the weight and the blade frame is keyed, bolted and welded as there is a lot of tension on this part. As is also apparent the frame would drop out when lifted so this was solved by two bronze discs on the top face which do no work except to keep things in place, all assemblies are pinned after set up alignment.

I had just enough hex bar for the vice part which helped, the large pulley is multi ply, this was machined and coated with resin and re-machined and mounted on a hub as I had run out of material for this,(a temporary measure which is still in service). Extra weights can be added but in practice are rarely needed and I have found the best blades are Eclipse Plus 30 bi metal HSS used dry as any lubricant seems to slow the cut.

I have just sliced of a piece of 2 inch EN8 bar which took under three minutes and is pretty accurate for this type of machine as long as care is taken in manufacture to make all faces square, I added a top guard from a piece of plastic pipe and the only purchased item has been a NVR switch working through an end of cut micro switch. I really wish I had made this years ago.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks