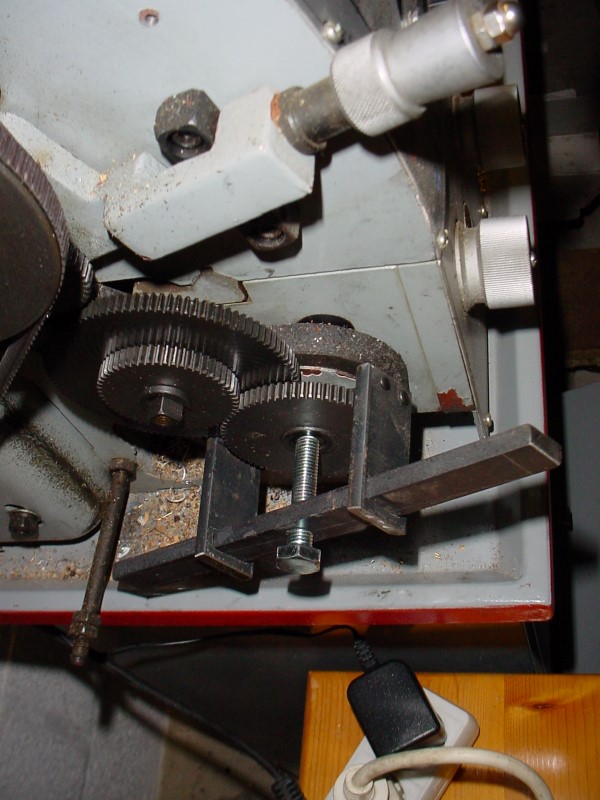

Another tool I needed, it's something to help extracting the gears on my metal lathe gear box.

They are always difficult to pull up with the hand.

So I came to this simple design, that can adapt to all the diameters I have :

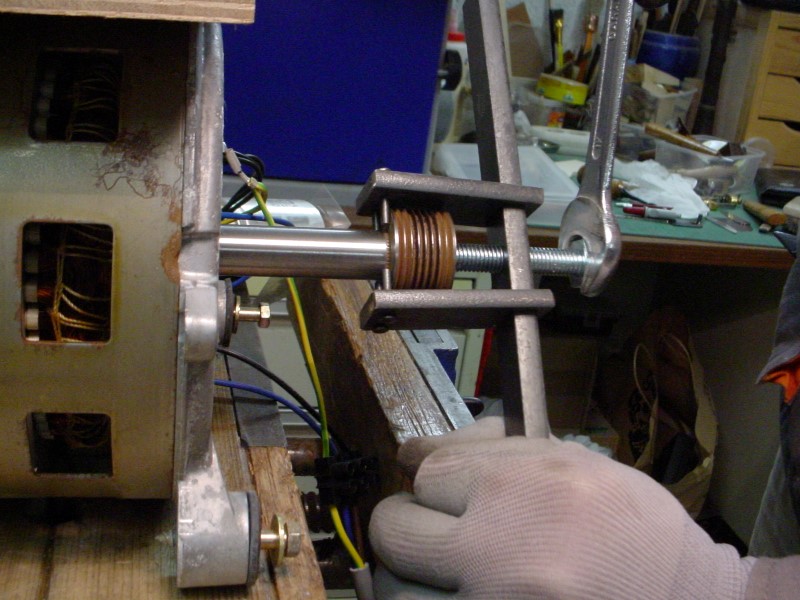

But I must admit that my design has a limitation. I tried to extract with it the pulley of my washing machine motor, the one I used for the disk sander, and I had absolutely no success.

The main bar started bending before the pulley started to move. It kept completely stuck.

So I had to build the sander with the pulley still on the shaft...

Actually, even if the main bar of the extractor has a good section, obviously, at the center, where the screw hole is drilled the section is too much reduced, and the bend starts from there.

It's a light duty extractor.

Anyway, it's still of great help for my lathe gear box.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks