Like many I use a floor jack, occasional other than strictly automotive projects too. On recent surprisingly good HF dual piston lift, the additional spreader was purchased. That means the normal 'cup' [more commonly known as a 'saddle'], pivot screw and small jack pad have nowhere to live. In my situation, that means lost or not handy when needed. Here's my solution.

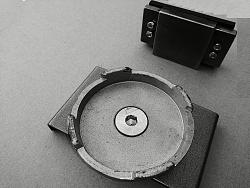

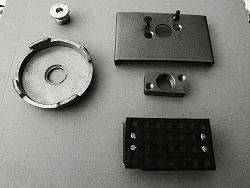

The small block is tapped 24mm x 1.5 to receive the pivot screw, fastened to sheet metal jack linkage cover with flat heads. The countersink is quite large and extends into the block.

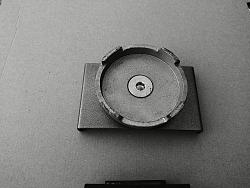

With cover plate remounted, the saddle is retained by corresponding pivot screw, hence the pad sits within cup portion of the saddle.

The pivot is broached for 10mm hex key, I haven't devised a satisfactory retainer yet, not wishing it magnetic.

The offset from center clears jack handle when upright; without obstructing motion of lifting arm up or down.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks