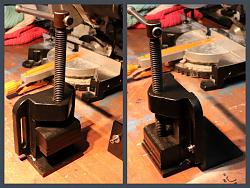

Found a broken drill press vise.

After years of use, it finally was drilled full of dimples and it was cracked. End piece was missing, but it tought it can still be usefull.

Fixed it by:

Straightening the end with angle grinder.

Then, filled dimples with my Telwin stick welder.

Finally made new end to it by welding 15mm plate to it.

Weld edges are chamfered, weld size is about A5.

Before welding i preheated it to 150 deg of celsius.

Welds are made using Esab OK 78.16 welding rod, 4mm and 144A.

Then i stretched the welds by hammering.

Finally wrapped it to insulantion wool, to cool it down slowly.

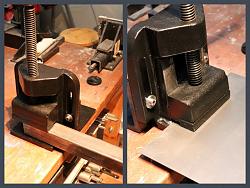

Also made removable support to it.

Now i can use it vertical or horizontal position.

Great for holding objects when cutting or grinding with angle grinder, specially plates!

But, works as a drill press vise too, or as a small press..

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks