I made this Finger Plate mainly for holding small gun parts to be milled, drilled, filed, ground Etc, most gun parts are very intricately shaped and difficult to hold with conventional tooling, a fixture of some kind is used in factories to hold these intricate parts, with this tool you clamp your work to the plate whether it be round or flat then take your work to the drill press, milling machine or surface grinder, all surfaces of this plate have been ground flat, parallel and square.

I’m in the process of building my second 50 BMG single shot bolt action rifle, I wish I would have had one of these when I built the first one, so before I get too involved in this next one I decided to make this tool, it’s going to come in real handy drilling or reaming holes and light machining in odd shaped pieces such pieces as the trigger, sear, safety components and disconnect just to name a few.

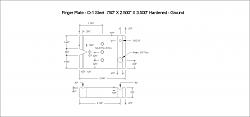

It’s a very simple tool in design and only consists of six parts, one Plate, two Fingers, one Drill Bushing and two ThumbScrews, the plate is made from O-1 tool steel hardened and ground, one finger is made from 360 brass and the other finger is made from 4140 hardened steel, the drill bushing is made from O-1 hardened steel and both thumb screws weremade from 4140 pre-hard steel.

The plate has two 90° V-Grooves, one small groove and the other a bit larger for accommodating different diameters of round materials, plus several holes of different diameters and a notch for thru drilling, driving pins, reaming Etc, there are two fingers one made of 360 brass and the other made from 4140 hardened steel, the brass finger is for holding something lightly without marring the surface of the work piece, the 4140 hardened finger is for holding something with a bit more clamping power if needed, the drill bushing fits into a reamed hole in the center of the largest V-Groove, this is for drilling top dead center of a piece of round stock up to .250” in diameter, different bushings can be made to drill any size hole I desire, this particular bushing I made will allow me to drill a .094” hole thru the work piece, I will make other bushings when the time arrives.

This would be a nice tool for model builders, people who build steam engines, or for anyone who needs to hold something you just can’t clamp in a vise.

I have included some photos of the machining process along with the completed tool being used and a photo of my first 50 BMG bolt action rifle, I have also included the cad drawings for anyone wanting to make one of these tools

As always thanks for looking

And happy machining

Doug

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks