I have a need for spiral wrap to protect hydraulic lines, to use in the orchard to hold drip irrigation lines, and probably a bunch more once I have the tool built.

If you have used this kind of product, you know how useful it is, but the cost caused me to pause - depending where you buy it it seems to be about a buck a foot. For reference, I can get 500ft of poly drip tubing for about $44 at HD, so about 9 cents a foot. So, why not make it from used poly tubing?

The tubing I have is used drip tubing. It had holes punched in it, but plugging and reusing for drip is less arractive than turning it into something else.

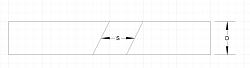

The tube is about 0.6" to 0.7" depending on the brand. When I looked at the commercial tubing products, I found that the spiral cut spacings (S) were about the same as the diameter (D) of the tubing, ranging from 1*D to 1.5*D

The spiral slice looks simply like this:

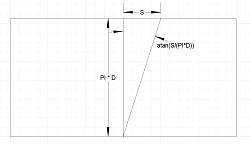

To figure the angle is pretty simple, we know the hose diameter and the slice spacing. If we unroll the hose drawing, it looks like this:

And - the angle is equal to atan( S / ( PI * D )) and knowing S ranges from D to 1.5*D we have a range of angles to be:

A1 = atan(S/(PI*D)) = atan(1.00*D/PI*D)) = atan(1.00/3.1415) = 17.7 degrees

A2 = atan(S/(PI*D)) = atan(1.25*D/PI*D)) = atan(1.25/3.1415) = 21.7 degrees

A3 = atan(S/(PI*D)) = atan(1.50*D/PI*D)) = atan(1.50/3.1415) = 25.5 degrees

Now to find the rest of the stuff to make the cutter...

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks