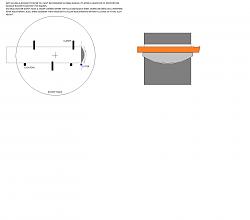

I may make or buy a QCTP for my Sherline in the future but for now I had this idea to use the rocker type tool post on the lathe.

The rocker tool post as implemented on the Sherline will allow easy change out without changing any tool bit height settings.

The rocker can be made with two rockers on one tool holder which improves speed even more. Anyhow that is how I see it so I thought it was worth a try.

Rockers were made on the CNC machine and trimmed by hand with a file.

The main blocks were profiled with the radius for the rocker on the CNC machine.

The holes were drilled on the CNC machine. Center hole was only spotted on the CNC and

then finished on the drill press. This required a .200" hole thru the part to the bottom.

Then the bottom was re-drilled .325" diameter to clear the shaft of the Sherline extended T-nut.

This re-drill stopped .300" from the top of the tool holder.

The holes for the clamping screws were tapped on the bench.

I bought 6 extended T-nuts from Sherline to save a bit of time. Only $3.00 each so my total investment in my QCTP is $18.00.

Should work fine, I made 3 single tool and 3 double tool holders for a total of 9 tool bits.

The black one is the one supplied by Sherline.

Cheers, JR

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks