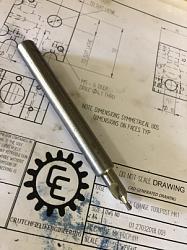

Having just acquired a mill with a round column the challenge of using different length tools to center drill, drill and ream without moving the head of the machine became apparent. A useful tip I found on the internet was to position the head to suit the longest tool. Given that the quill stroke is only 100 mm. and that the reamer, and the drill are significantly longer than the standard center drill this may be not always be possible. I made an extended center drill by using a piece of 12mm BMS about 100 mm long. Centered and drilled a pilot hole 0.5 smaller than a center drill I had available using this I drilled the end of the shaft because there was not much material to remove the swarf was not a problem. The fit between the shaft and the center drill was surprisingly good. I then secured the center drill in place with locking compound. The performance has been very satisfactory when the drill fails, I will simply heat the end of the shaft with a torch to degrade the locking compound and reverse the drill.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks