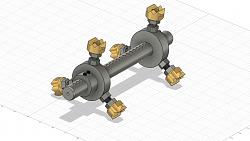

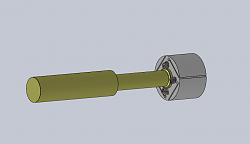

Cutting a large thick-wall tube to make antenna support rings on my lathe was a big challenge. Southern Comfort and too much coffee resulted in an internal mandrel fixture that works quite well. I can now hold large heavy tube and machine the outside and both ends with ease.

I can't claim any originality for this fixture. It's probably got a proper name but I don't know what to call it. "Expanding Tube Mandrel" will have to do.

I don't have a steady rest, but machining the outside and ends of a tube when using a steady rest means a lot of extra steps, and this thing can stay with the workpiece if I part off a thick ring then want to machine it before cutting another. Once the lathe is clear again, I can just pop the tube back on, complete with the mandrel still inside. Also, finding a big enough steady rest to fit 7+ inch tube on my Colchester 1800 would be amusing.

This is Part One of the video, second part to follow soon.

Now I've mentioned steady rests, I want one of those as well. Too many projects, too little time.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks