I wanted a simple draw-bar driver to make tool changes quicker and less tiresome on my milling machine.

I didn't want to use a compressed air system, as each time I'd need to use it I'd have to run the compressor to reach working pressure.

I often use the mill to just drill a hole or clean a face and running a compressor seemed overkill and noisy.

I have experience in making expensive smoke from electronics, so avoided even simple electronics.

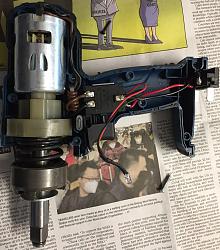

After some brain exercise, I came up with the idea of using a Ryobi cordless impact wrench which was available and inexpensive at my local hardware.

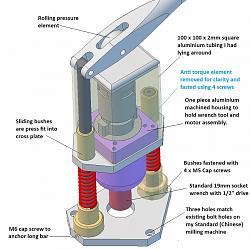

All material used I had lying around the workshop. The aluminium parts were Alodined to keep it looking smart.

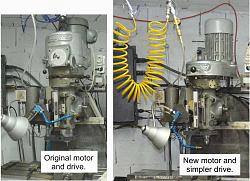

The various disassembled Ryobi elements and existing bolt holes on top of my milling machine guided the rest of the design.

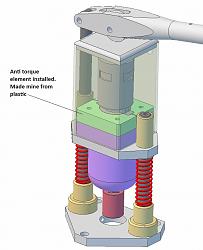

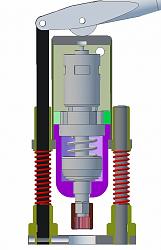

I would make a new housing for the impact wrench / motor assembly and retain the plastic Ryobi pistol grip body with its controls on the end of a hinged arm, placed in easy reach.

To operate, I pull the handle down to engage socket wrench onto to top of draw-bar and press trigger to tighten or release. The springs pull it back up to disengage socket thereafter.

Occasionally after some heavy milling, the collet is tight in the spindle and after using the impact wrench to loosen draw-bar, just lift handle and pull it down firmly to release collet.

I've used this electric draw-bar for past three years and it works just great. Much quicker and easier than the old method with spanner on the end of the draw-bar.

I used my phone to make a video clip to demo how it works.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks