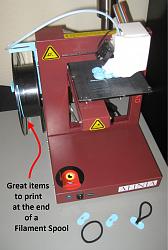

I end up with filament spools with just a few wraps left on them, so it is nice to have little items to print.

Use what you have ...... and Brenda has elastic hair ties which make nice cord wraps when used with these 3D-Printed ends.

Also work to hold other items ...

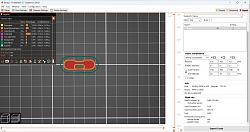

The .STL files for 3D printing are on GrabCAD

https://grabcad.com/library/cord-wrap-3d-printed-1

Nothing fancy... but they work for what I need.

... CHEERS!!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks