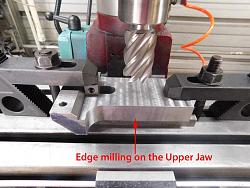

In my last post I fabricated and submitted a couple of Carbide Insert Tool Holders, which is not a new invention by no means, just my version, I made a lifting fixture to hold the tool holders up off the milling machine table to machine the edges and to avoid cutting into the mill table, I thought after I was done that some sort of tool that would clamp work on its edge would be nice to have for times like this, so that’s what intrigued me to make this tool I call the Edge Milling Vise.

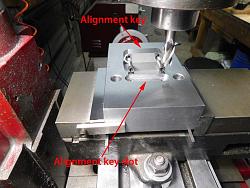

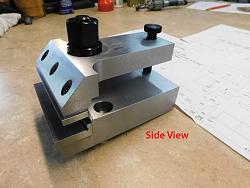

The vises dimensions are 4” wide 6” long, the vise has hardened Jaws inserted into a recesses machined in the Base and Upper Jaw, there is a 5/8” alignment key in the bottom of the vises base to accurately locate it in the T-slots of the mill, the front of the Upper Jaw is machined at 45° to give sufficient clearance for milling close to the edge of the vise, the Upper Jaw can also slide in or out .375” to give additional milling cutter clearance, the sides of the upper jaw has been reduced in width from 4”at the front to 2 ¼” in the rear to give away access to the two 1/2"socket head cap screws that holds the vise down on the mill table, the vise can be rotated to any angle by removing the 5/8” key from the bottom of the vise, the vise can be set at any angle with the useof a protractor, angle plate Etc.

The vises body was made from 1018 steel, the upper and lower jaw inserts were made from O-1 steel hardened and ground, the stud, nut and washer were made from 4140 steel.

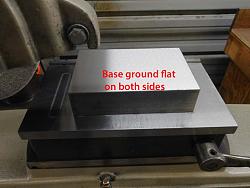

I started out by grinding all surfaces of the vises base and upper jaw parallel and square, I machined a 5/8” alignment key slot in the base along with two 1/2" counter bored holes for mounting to the mill table, the 5/8” alignment key is secured in the keyslot with two 10-24 socket head cap screws, the base was then flipped over and inserted into the T-slot of the mill table and bolted down with two T-nuts and two 1/2” socket head cap screws, I completed all the machine work to the base while it was bolted down to the mill table before removing , the upper jaw was then fabricated along with all the other hardware items, this vise is solid and very rigid in construction and functions as intended,

I have included multiple photos of the machining process to make this vise along with a demonstration video.

As always thanks for looking and happy machining

Doug

<span style="font-family: Calibri"><font size="3"><font color="#000000">

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks