The punch marl looks slightly to the right not centered.

Ralph

The tool and method are explained here in another post (Marking GAUGE CALIPER). But there are other options, for example, attach to the chuck lathe and make the divisions using the plate's own fixing nut. You can also use a saw disk as a template (here are some examples) or a dividing head. If you do not have any of these features, then the old tracing method should be used. Thanks again Ralphxyz!

Last edited by machining 4 all; Nov 30, 2020 at 08:59 AM.

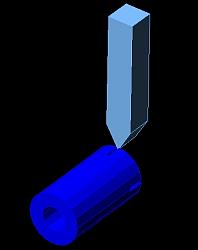

I made it on the milling machine, with the help of a dividing head (this head I have shown here too). I attached the tool (photo) to the mandrel and moved the X axis by 6.0mm. After the process, I painted with black automotive paint and sanded (mesh 220) on the lathe. It was very easy and fast! But as I said, you can use other methods if you don't have a splitter or a milling machine...

Last edited by machining 4 all; Nov 30, 2020 at 09:44 AM.

When I have irritated skin, I use gloves, because I have skin problems (I rarely operate the machine in motion using gloves). Cutting from the inside out is a little more difficult, as the tool needs to dive into the part. I prefer to cut from the outside in, the burrs can be easily removed with sandpaper.

Last edited by machining 4 all; Nov 30, 2020 at 10:31 AM.

There are currently 1 users browsing this thread. (0 members and 1 guests)

Bookmarks