As you may already know, there are two kinds of vacuuming systems, serving two different purposes.

- The Low depression / High volume for chip collection, typically for wood working machinery.

For this you need minimum 100mm diameter hoses

- The High depression / low volume system, similar to the household vacuum cleaners

For this the hose are generally, at the suction end 32 mm diameter, and when you have a collection network in the house, the PVC hoses are generally 50mm in diameter.

I already have in my shop a Low depression/High volume system with a big cyclone and homemade turbine (never showed that, need time to publish that), with 100mm hose.

But for some applications, like vacuuming the debris from a high speed CNC spindle, of for lifting the metal chips to clean up a conventional mill, this is not really relevant and you need more suction power and so more depression.

For that application I generally use a small shop vacuum, but it always gets on my way and so I decided to install a vacuuming network at the ceiling of my basement shop, and control the shop vacuum with a remote command.

There are lots of benefits doing this, first of it being I reduce a lot the noise in the shop, especially at the CNC (I now use a water cooled spindle which makes much less noise already compared to an air cooled one).

Other big advantage is that It also improves a lot the air quality in the shop, because shop vacuums can be powerfull at sucking the dust, but they are also as much powerful at blowing air in the shop and lifting the dust all over the shop.

The shop vac I use has a blower feature which even allows to connect a hose and blow the air out of the shop if need be.

Here are some photos of my setup :

End connection to the CNC dust shoe (see my other post about this one)

Connection of the CNC hose to the port just above mounted on the ceiling :

View of the PVC hose network, heading towards the shop door, where the remotely activated shop vac is installed.

Here is the port above the conventional mill, closed when not used.

I use it on the mill mainly to cleanup metal chips, but as I don't want metal chips in my network, or in my central vac, I have a small cyclone next to the mill to collect these metal debris.

And here is where the shop vac is installed.

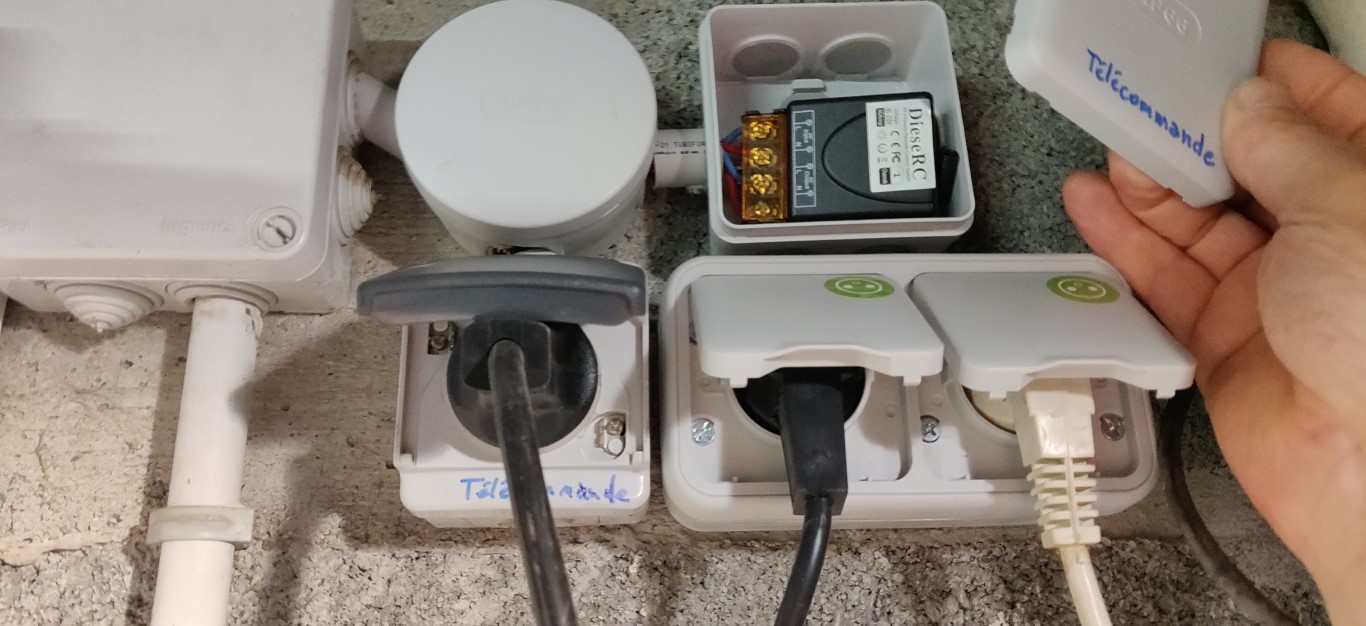

You can see on the wall this connection box, and sockets marked "TÚlÚcommande", meaning "remote control".

The box is were is installed the remote controlled relay that is used as a switch to power the socket where the shop vac is plugged in.

Here is the remote control box open.

And here is the remote control itself, it's radio activated and can reach up to 100 meters away from the relay, it works like a charm.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks