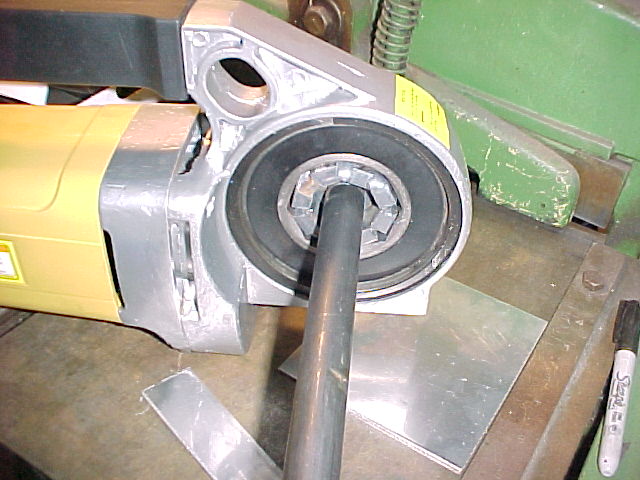

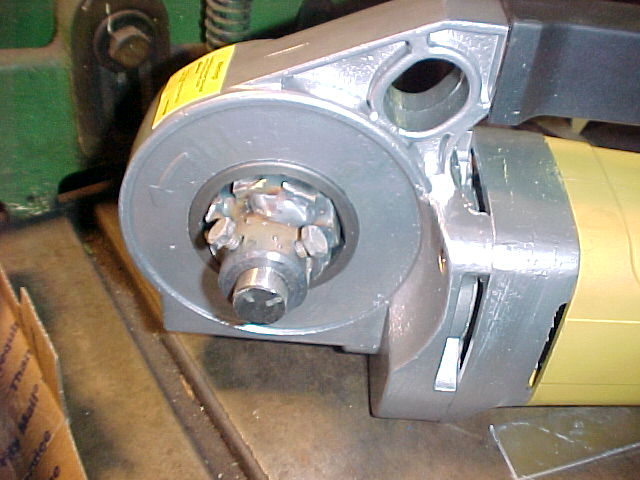

Doing the SWAG mod to my Harbor Freight tubing roller. They say to just mash the 1/2" threading die onto the 3/4" drive shaft for the roller. I want to keep the 1/2" die usable so I designed an adapter to fit the octagon drive bore in the threader. This is an 8 sided bore. It would have been to easy to make a 6 sided one.

The HF Pipe Threader.

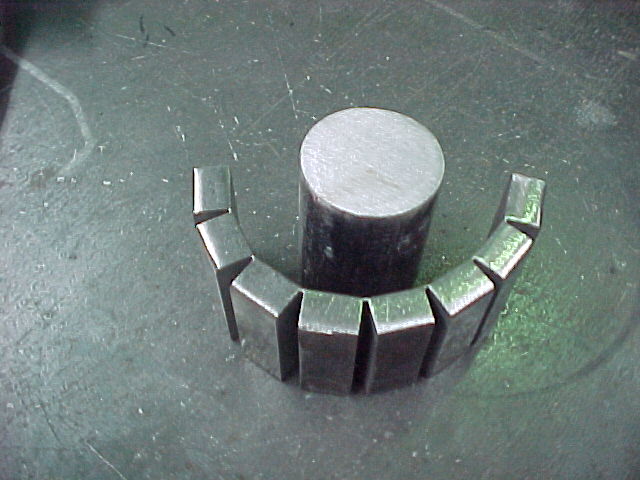

This is one of the original dies... 8 sides, not 6... Is this a "metric" hexagon?

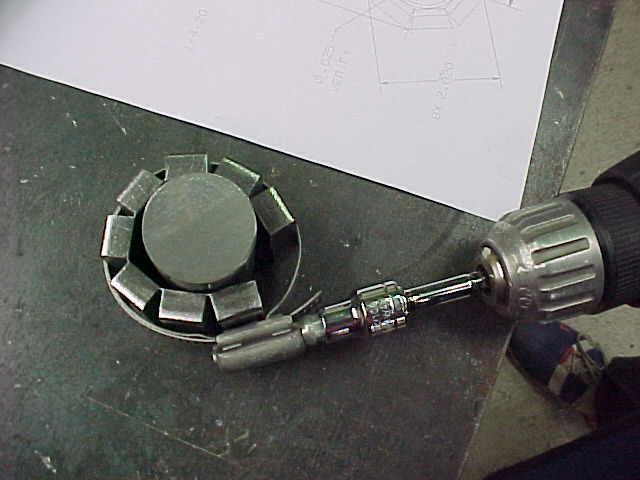

I designed the adapter in 3D CAD so it was easy to get good dimensions. I first designed it by cutting 8 chunks of 3/8th's plate but thought it would be easier to assemble if they were all one piece.

We laid out all of the cut lines and clamped the plate to a small angle block.

Doing all of the cutting on VBS was pretty quick with the layout lines and block clamped on to guide the initial cut.

The spacing was .526 inches between the centers of the cut. With all of the cuts made.

See next post.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks