I know that there is a proper way to do this, who will be the first to tell me?

I want to drill holes in steel ball bearings to make tommy bars for clamps.

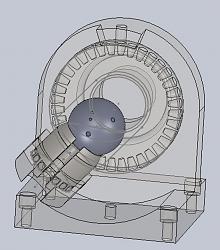

This is the method I devised

You see that I have filed a flat prior to centre punching.

I have taken a hex nut, cut through one flat, and half way through another. Then I hammer the ball bearing into the nut. It looks central to me, but I have no way of checking. Then I squeeze it in the drill vice

Tap it down so that, as far as I can see the flat is at right angles to the drill bit. The nut is supported by a scrap of beech off a chair, that has a countersunk hole in it.

Not sure that you can see, but Iíve drilled about halfway through the ball. I shanít tap it, but epoxy a bar in the hole.

Now, all you engineers can have a good laugh!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks