Please ignore this post if you already know how to drill brass safely!

Hi All

One material I am not keen on machining is brass. It is not a difficult material to work with but there are some issues when machining. Also the brass swarf gets everywhere and makes cleaning down the machines a nightmare.

Anyway getting back to drilling brass.

When drilling brass there are several things to be aware of when using a standard 118 degree twist drill. Cutting speed 90-210 m/min, Coolant, drilling to required diameter in one pass (not stepping drill sizes) But most important is drill point preparation.

A standard drill tends to snatch at the brass and drag itself into the workpiece.

To prevent this the cutting edge can easily be modified with either a oil stone or my preferred way is a offhand grinder.

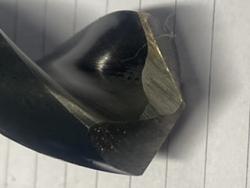

The photos below show the drill point for brass.

Both drills are 20mm diameter. The lower drill is a standard drill and the one above has been modified for brass.

Right drill has negative rake for brass.

Centre drilled and drilled at 20mm so the drill has less chance of snatching. If the hole was to be 30mm diameter a 30mm drill would have been used after centre drilling.

Drill chips are removed like small needles.

Brass swarf collected on a rag to aid clean up.

I hope this will be helpful to those that are not use to machining or thinking of using brass in there future projects.

The Home Engineer

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks