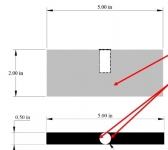

Say I need to drill a 1/2 inch hole in a 1/2 inch wide bar. How can I do this without severing the bar? I recently had to solve this problem.

If you are interested, please see

https://rick.sparber.org/HalfInchHoleHalfInchBar.pdf

Your comments are welcome. All of us are smarter than any one of us.

Thanks,

Rick

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks