I want to mill printed circuits boards (PCB’s). The required small mills demand for a high speed. So a Dremel with 30000 tpm is an adequate tool. The cross table of my drill-mill is very useful when the copper traces are orthogonal or under 45 degrees.

I don’t have a CNC mill but a simple hand controlled drill-mill.

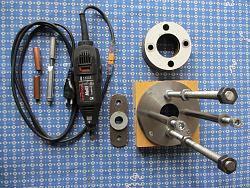

I started some years ago with a quill clamp which holds the Dremel besides the machine head (picture 1).

This design has a drawback: the quill has angular play which changes the position of the Dremel wrt the work piece.

So I decided to make a Dremel fixture where the Dremel is mounted centrally to the quill (picture 2). To limit the length of the fixture I directed the power cord through the spindle boring. To that end it was necessary the cut the power cord of the Dremel and provide it with a small (11 mm) plug and socket, small enough to allow passage through the boring (picture 3). The soldered connections are isolated with heat shrink and hot glue.

The Dremel itself was screwed in a PLA nut, 3-D printed by a friend. The nut was pressed and hot fixed in a steel strip (picture 4). 3-D printing screw thread seems to be difficult for, in different trials, the threads where always to small. So I made a tap for this non standard thread (¾”, 12 tpi, 60 degrees) and widened the thread. (Alternatively an alu nut can be made with the same tap.)

The Dremel is supported by an enclosure made from 4 stacked layers of 8 mm compact laminate sheet (see pictures 2 and 6). It ensures a stiff mounting without side movement.

For clamping the fixture to the quill I used 32 mm plywood (pictures 2 and 5). Perhaps it is not the best material, but it was the only material of sufficient thickness I had in stock from a discarded kitchen top. The hole encloses the quill’s collar narrowly and is fixed by a pair of alumin(i)um cotter pins (British naming) (picture 5). The hole in the clamp for the cotter pins is provided by a copper tube in order to let the pins slide easily.

My Dremel is an old model. I noticed some radial play in the Dremels spindle. Dismantling showed that it was not the bearing itself but the bearing house. I filled it with small pieces of 0.1 mm milar sheet. Now the spindle is without any play.

This design is giving a very stiff mounting thanks to the 4 vertical studs. The shorter two are made from 12 mm round rod, the longer ones are 10 mm threaded rod.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks