Dog Point Screw

A screw with a non-threaded point is called a "dog point" screw.

Dog point screws have several applications:

- Set screws or grub screws often have a dog point to avoid damage to the starting thread as well as the part being secured .

- A dog point fastener can be used to help align a cover with a threaded hole, or similar application.

- A screw or bolt with a dog point is highly resistant to cross-threading.

I was making some fidgets for a family member using some threaded rod ("all-thread") and wanted to avoid cross threading. I was making a number of these in varying thread sizes, so I needed an easy way to manufacture them.

Making a proper dog point is more complicated than simply using a lathe to machine the threads off. Cutting the threads off squarely leaves a very sharp and fragile edge at the start of the thread (where the cutting stops). This sharp edge would need to be filed or ground off. This is simple at the end of a screw, but not so simple with the dog point shape.

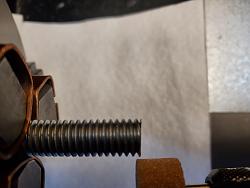

[Left, square cut thread (not a dog point); Right, dog point made using method described]

Tool Post Grinder

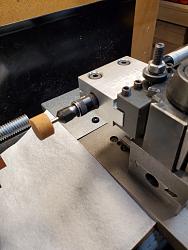

I have a Dremel tool with a flexible shaft attachment. It is one of the older styles where the "handle" of the flex shaft is (conveniently) a cylinder. I made an adapter to secure it in a quick-change tool holder so that I can use it as a tool post grinder.

Using the flex shaft (vs. mounting the Dremel tool itself) reduces weight and stress on the various parts of the mini-lathe. Be sure to hold or secure the body of the Dremel tool as varying load on the grindstone can feed back through the flex shaft and cause the tool to move around.

The Method

Set up the lathe as follows:

- Configure the lathe gear box or change gears for the thread pitch of the screw.

- Hold the screw / rod in the lathe chuck. Use soft jaws or soft pads to avoid damaging the threads with the chuck.

- Align the compound perpendicular to the cross slide.

- Mount a small cylindrical grindstone in the tool post grinder. Diameter of grindstone should be selected based on the screw diameter and depth of the thread.

- Position the tool post grinder on the tool post with the axis of the grinder parallel to the shaft of the screw.

- Install a hand crank in the outboard end of the lathe spindle.

- Cover the ways to protect them from grinding debris.

Procedure:

- Use the carriage to move the grindstone close to the end of the screw and engaged the half nuts. Leave them engaged throughout the procedure.

- Use the compound to align the front corner of the cylindrical grindstone with the thread on the screw.

- Start the grinder and use the cross-slide to set depth of cut.

- Use the hand crank to slowly rotate the screw and advance the tool post grinder along the screw thread via the lead screw / half nuts. Turn the crank as needed to create the desired length of the dog point.

- Multiple shallow passes may be required depending upon thread "height" and hardness of the screw material. Adjust the cross slide and compound as needed.

The round side of the grindstone leaves a very nice profile at the start of the remaining thread.

If you don't have a hand crank, or if the screw is too long to allow crank installation, just turn the lathe chuck by hand.

It should be obvious, but don't power the lathe.

Theoretically, this method would work with almost any size screw. In practice, the precision of the corner of the grindstone will limit how small you can go.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks