Nothing new around here - merely my cheapskate take on a Über-purpose lo-rev TP drill/ mill and grinder...

Just for light duty (<150W in) work as machine rigidity is not one of the many virtues of a 7 x 14" mini lathe.

There's been a few of these around here and on YT - so I might as well pitch in?

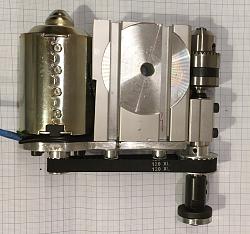

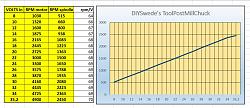

"Design considerations": Cheap-to-the bone with mostly dumpster diving finds such as the sturdy Al extrusion, the 59 mm dia motor from an OKIN Deltadrive linear actuator, the Mean Well (sic!) 30 VDC 5.6 A switched PSU, a few bolts and an actually bought, cheap set of axle, 1/4" chuck, bearing block, belt and 2:1 pulleys + a 50 V 20A PWM controller, giving the following revs (CW or CCW):

Guess the only original idea of mine was to make it "Flip-Flop": so as to get it in from just about any angle and direction?

Turned the center portion of the extrusion's top and bottom, for 360 deg rotation and on-center height on both sides...

Axial drilling/ milling, inner or outer cutoff wheel (slooowly!)/ grinding (-Use "bedsheets"!) :

4 mm Keyway milling a few minutes at 2 kilo-rpm (and this won't wake my next of kin, as the 400W 20k rpm Screaming Hilda, see:

Free from scraps: angle plate, milling slide and tool post grinder mount.

No big deal, but it'll come in handy - and it only cost me about 10 bucks, all in all and a few hours of winging/ fiddling.

Yeah!- you can hardly hear the thing with the German made OKIN motor!

"-It werks!"

Quick, Dirty, Cheap & Operational - as always from DIYSwede's "Walk-in Closet Workshop"

Hope someone'll find some useful tips or entertainment from the above.

Cheers

Johan

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks