I recently bought a cheap (very cheap! $22 shipped) hole puncher shown in the first pic and was amazed at how nice it works. It punches round holes in light sheetmetal easily. I started to think this would be nice if they had one for square holes but a search quickly showed me there really isn't anything like that available. You can buy dies for large machines but they are very expensive.

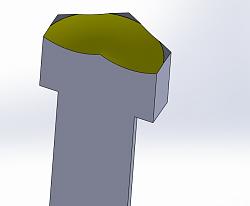

I decided to try and make a square hole punch myself just to see if it could be done and how hard/easy it would actually work. Taking the easy approach, I opted to use sockets and socket adapters as they are already the right shape and most importantly, they are already hardened.

The male part of these extensions have a rounded edge so I ground it flat to get more of a sharp edge. The female part of the socket has a chamfered opening so I ground them down a bit to remove some of that. I used a grinder and a belt sander to do all of these.

Since I already had a nice jig made up as a finger brake press for my shop press, I simply made parts to fit it. The top piece is made so it gets sandwiched in and the bottom plate has a set screw to lock it in the correct position so the two parts meet up correctly to punch the hole. The bottom dies (sockets) have been modified with a collar either in or around them so they all fit the same recessed hole in the base plate.

I've tried 22 gauge, 18 gauge and 16 gauge sheet steel and each worked very well. I have no plans of trying anything thicker but wouldn't be surprised if it didn't work on that too.

The nicely shaped square waste pieces could be useful for filling/welding holes shut or ?? so I'm saving them being the pack rat that I am.

This is really in the "prototype stage" so many more improvements will be done but it is very functional as it is shown. One improvement I would do next is to add what is called a "stripper bar". NO, not that kind of stripper bar! An adjustable bar made to sit on top of the sheet metal to hold it down when the punch die is lifted back up.

To get a cleaner punched hole, I plan on removing all of the the chamfer from the sockets. As it is now, it does slightly dimple around the hole (that might even be desirable in some cases)

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks