Home made milling machine - Maximum DIY style.

For years I've always wanted a milling machine but they are too expensive and I just couldn't bring myself to pony up to dosh. So I decided to make one myself out of spare parts I had laying around, the results are pretty amazing.

It's not an industrial machine and it seems to work fine making small cuts - perfect for my needs.

Parts used:

The power spindle motor is a 2400 watt electric motor salvaged from a paint sprayer pump.

The power feed for the Z axis (up and down) is the climb motor from a treadmill - this is a strong geared motor which is used to raise and lower the spindle head.

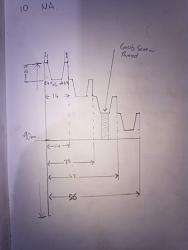

The X axis (left and right) power feed motor is a 12v window wiper motor from an old car - the speed control is a 12v 20amp PWM circuit. The power feed is manually engaged by using a 19mm 12point socket that can slide back and forth connecting the powerfeed drive to the table using a hex head on once side and square on the other, once engaged the table will move back and forth at the desired speed. Please see photos attached

The pulleys were all hand using the lathe made as they are quite expensive, the switches, plastic boxes, bearings and machinist vice were all purchased from eBay in an attempt to keep the cost down.

Parts made:

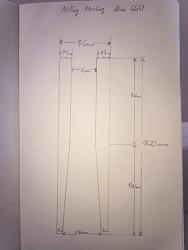

The main support column was made from an old bench grinder stand - I placed it on the lathe to square it up and it worked perfectly. There are various other parts that were made on the lathe such as the main shaft, this is a 35mm steel shaft that uses an internal M3 taper to house the cutting tool which is held in place by a head bolt connected at the top of the spindle shaft.

This is tried and tested method on professional machines to prevent the cutting tool from leaving the machine due to vibration.

Spindle: The spindle was hand made on my lathe out of Bright Steel from memory it was 40/40 cold rolled steel.

Taper: The taper is an Morse3 taper, I decided to use this shape as tooling is quite cheap and will also fit my lathe tail-stock.

Bearings: The bearings were I used were pillow block cast bearings UCF207 35mm ID, they were the only bearing in my price range and they seem to do the job well.

The compound table was purchased form a machining store as it's quite strong and sturdy and far too difficult to build without access to a professional milling machine. The 4" vise was another eBay purchase - links below

Accuracy:

The home made spindle has a run-out of 0.004mm which isn't too bad for a DIY job.

If you like this video please leave me a comment - Like / Share / Subscribe

Thanks for watching

Powerfeed images

Ebay Parts listing

ER32 Collet Set

https://rover.ebay.com/rover/1/711-5...72.m2749.l2649

4" Milling Machinist Vise

https://rover.ebay.com/rover/1/711-5...72.m2749.l2658

M3 Face Milling Cutter

https://rover.ebay.com/rover/1/711-5...refresh%3Dtrue

Pillow Block Bearing UCF207 35mm

https://rover.ebay.com/rover/1/711-5...item521a81bdc0

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks