A regular drill press spins too slowly for very small drill bits and parasitic forces reduce the "feel" for what the drill bit is doing. Both of these factors often contribute in a major way to broken small drills.

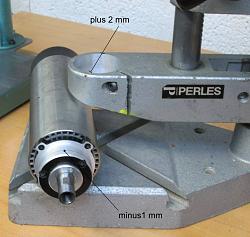

For some time I have been thinking about making a sensitive high speed drill press using the high speed spindle that I use only occasionally on my mill and also lathe. A few days ago a drill press meant for pistol drills came up on a local classified for sale list. It was of higher quality than most items of that genre that I have seen, and I bought it for only 20 euros.

Click images for full size versions.

Only a minimum of work was required to mount the spindle on it but a little more work was required to make and fit a counter-weighted balance system.

I have made a 20 minute video which explains the conversion as well as demonstrating the requirements of a sensitive drill and showing some tests of how I checked the success of my efforts.

Don't forget to like and share the video, and subscribe to my channel for news of new videos.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks