Hi All,

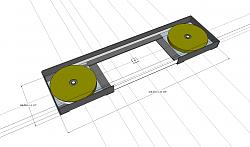

I'm in the planning stage of a DIY Band Saw build and wanted to ask a question as to the efficacy of using a rubber wheel (think wheelbarrow wheel)?

Originally, I planned to make the two discs of the band saw out of some type of engineered wood (melamine, osb, plywood) and just insert my own bearing and run some rubber on the edges.

However, I was browsing my local hardware store's website and found these rubber wheels which are the exact radius (albeit twice the width).

There are many benefits to going this route (the bearing is already inserted) and you don't have to cut and round a wheel.

However, I'm wondering if anyone used such a wheel before? Does it have a lot of "give" to it? Will it still be able to run the blade straight? Or will it buckle easily under load?

I've not yet had the chance to drop by the store and press the wheel to see if it is soft or not.

Thanks

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks