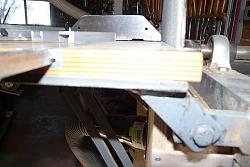

After having built myself a belt sander someone asked if I would build him a disc drum sander. So I went o work on it and built this disc/drum sander. He never did come to buy it or to see it so I kept it for myself. It is belt driven by a 3/4 hp motor inside the box which is open from the bottom for ventilation. The tilting table is 1/4" plate with a plywood top on it. It features a slot for the miter gauge as well as a slot at right angles to the disc. There are 2 pieces of T Bar in there with bolts and knobs under the table. I made various insert to fit in there from pieces of aluminum miter track to either fill the gap or to use as guides like the piece laying on the side which has a compass point for truing up circles.

On the other end it is a drum sander. The table is a router table plate with those red removable insert rings. This way I can accommodate many sizes of sanding drums. The table is tiltable as well as sliding in and out as needed or can be slid right out. I can use flap wheels as well as mop sanders and inflated soft drums or a wire wheel or even another disc, anything that will mount on a 3/4" shaft.

It is probably the second most used machine in my shop after the table saw.

Nick

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks