I have been wanting to make the air compression of my home-use air compressor to a tad weaker pressure. I sometimes use rather weak compressed air for air cylinders and air brakes on a tool I use. The compression required for these air units is mostly 0.1 - 0.15 M pascals, in an average something like 0.12 M pascals.

But my everyday use compressor has a higher compression, which has been set for air tools like air grinder, air impact wrenches and air dusters in my shed.

So have made up my mind to arrange some parts and units for a new homemade air compressor, with a digital air pressure controller too.

Showing below is a set up for a Laser displacement detector at the back, but not seen here though.

White rectangle box at the center bottom is the controller. A grey cylinder in the right upper is an air buffer tank.

Case was made of card board, black cord leads power to an AC-DC converter that makes 24 DC volts. This converter was from a tad troublesome set up of Fluke handy oscilloscope, which needed some repair.

A white small box sitting in the lower box(which is a lid) in the left is a positive pressure sensor, this works in 24 DC volts and is connected to a relay.

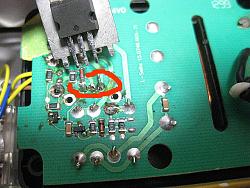

The trouble about this AC-DC converter was that its MOS-FET transistor, it was gone.

Replaced it with a new one.

The setting on the sensor is so called Normally Close, with which the pump starts when you plug the line in.

Now the pump is moving and this indicator shows pressure in red.

It stops when the pressure goes to any set value, e.g. 0.120 M pascals in this case, and the indicator turns to green.

This unit can be used for other small home-use air compressors. If you need higher pressure you only need to give a couple of alterlations to the setting. The maximum serviceable pressure is 1.5 M pascals.

Chy

Incidentally try to choose larger relay with the capacity like 15A or more for your air compressor, since the motor requires bigger amperage when it starts.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks