No argument when it comes to boring heads the way to go is with a dovetailed slide with index-able adjustment screw.

But not everyone can afford to buy a good one or simply do not want to have to drive to the machinist supply store. So they make their own and several here on HMT.net have made some really great ones.

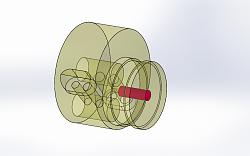

I am working on a project that is going to require 2 holes bored in 1 inch steel plate these holes will need to be somewhere in the neighborhood of 3.5" or just under 90 mm. SO I started digging around for some scrap pieces to make a boring head out of I found a cutout slug from a piece of ASTM 514 or T1 steel, about 1 1/2" thick and roughly 3 3/4" diameter perfect for the main body then I located a piece of cut off mystery round bar 3 inches long and 2 3/4" diameter.I'm pretty sure it was left over from some excavator pins I made but don't remember if I even knew what steel it was. anyway it was the only piece I had, this would work perfect for the sliding cutter holder.

I'm all set but there is only 1 little problem my dovetail cutters are packed away over 200 miles away. I called the nearest supply house that might have one about 85 miles away but they would have to order one if I could wait 2 weeks for it there would be no freight but if I needed it in 3 days or less it would cost me an additional $30.00 shipping. Forget that I said I could direct order one and have it in 3 or 4 days myself with no shipping charges.

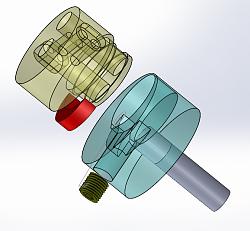

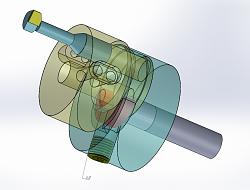

But I'm not going to do that either. I'm going to make a boring head that doesn't need a slide dove tail T slot or other. I'm going to make a double eccentric and I'm going to make one that anyone can make who has a lathe and a drill press but little other specialized tooling.

to start off I cleaned up the slug to make it round with reasonably parallel ends. then I chucked it off center in my 3 jaw my reason for doing this was on my lathe it is a drama extreme to change from 3 to 4 jaw chucks then back again this can take an hour and a half due to the spindle nose on my Leblond lathe. Additionally I thought a lot of guys may not even have a 4 jaw chuck . To be honest after I had machined the eccentric bore I thought about I could have simply welded a short piece of shafting on the back of the cleaned up slug set off center where I wanted or needed it to be do the machining then saw it off LOL Hind sight always improves after the fact.

Next I recenter the part and machined a .500" groove for the tool holder lock.

Once that was done I cross drilled a 1/2" hole for the set screw I needed a 17/32" drill for the 5/8-11 thread but I don't have one, so I did the next best thing after drilling the 1/2" HOLE I ran a tapered reamer down it the reamer starts at .375 and ends at /625 I ran it in a little over half way then there was no problem tapping with a tapered starting tap

Next I chucked my tool holder block again off centered After machining it I noticed I had missed the offset by a few.000" and did not get a full round clean up I was going to leave it until I also noticed that I had transposed the distance of the locking grove which meant I had the groove in the wrong place by .125" which would mean my crescent shaped lock piece was going to be a problem.

New problem no more stock of this size so either have a sloppy under width lock crescent or weld up the surface and re machine it this would mean I could correct the previous offset mistake as well.

welded up and re machined now to bore the tooling holes Since I needed to offset even further I could not use a space block under one of the jaws so I clocked #3 4 turns of the scroll #3 is the best jaw to clock since when removing them for cleaning #3 is the first one that comes off and the last one to be put back on.

Next I tried to mill 2 flats for the set screws to secure the cutter tooling. the only end mills I had were 20 pc a set that was given to me last Christmas unfortunately they are better suited for milling soft air than actually having to cut steel. I had used a couple of the 2 fluted ones on aluminum nut had never tried to mill steel other than what I knew to be mild steel or 1018 cold rolled On this stuff though even with coolant the HSS end mill only managed to make 1 cut before becoming so dull it wouldn't do anything. SO I put a short carbide tipped boring bar in a collet then finished making my flats then drilled the 4 holes with a 5/16" cobalt drill bit. Tapping to 3/8 16 was an adventure but I managed without breaking a tap

Next was to make the crescent lock piece . this was made from a piece of cylinder I found laying around that had roughly the correct inside diameter I cut a segment then ground the outside to shape

Finally the assembly and a mock up test to check the cutting range. it turns out that in the outer most hole the range is from about 2.5 to 4.25"

I'm happy and will be really happy when I see it bore the parts I need.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks