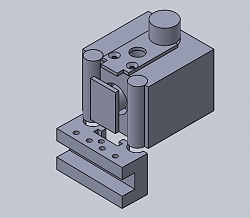

This is from an original design by J A Radford and was featured in the Model Engineer.

The main advantage of this design is that it can be made without the use of a milling machine as indeed was mine and has been in use for 40 years on my South Bend.

I can vouch for its sturdiness in use and it will still repeat to .0005 inches, it also gives a little more room when working close to the tailstock.

Mr Radford as I recall made a drilling jig for the dowel locations and drilled and reamed on the bench drill.

I did not follow that approach myself and instead jig bored them using my vertical slide, I am glad I did as I have only recently made some more tool holders and after all that time I doubt I would have found the jig.

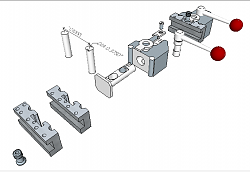

I do not have the original drawings but have re drawn it to scale on 3D Cad (Sketchup) and have taken a screen shot to show the parts. The sizes are to suit your preferences but on mine the dowel ctrs are 2 inches and the centre clamp ram is .750 inches. The only other relevant dimension is the offset of the cam clamp which is .0625 (could be a little more say .075). The keen eyed will notice that the drill rod location pegs are screwed to the main block, I think that modern adhesives would probably do the job just as well.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks