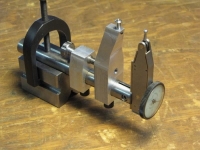

Like most neophyte machinists I soon realized that I needed a tool height gauge for setting the height of my lathe tools. My research uncovered a succession of what I can only describe as the most over-designed, complicated, hard-to-use devices I could imagine. As a devotee of the idea that simple is better I made a gauge that consists of nothing more than a block of steel relieved on the bottom...

so that it will sit flat and not rock when placed on a flat surface. The height of the block was carefully machined to match the height of the lathe spindle above the top of the compound. (Thankfully, my compound has a flat top; not all lathes do.)

Its use is simple. Push it up against the tool tip and slide your thumbnail back and forth between the gauge surface and the tool. Millions of years of evolution have made our fingers extremely sensitive; you'll be able to detect a few thousandths height difference and tell whether the tool is high or low as well.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks