I had a spindle from the tail stock of a large lathe which I used as the basis for an accurate cylindrical square. Although the spindle was hardened it had some wear due to years of use on the lathe. This video shows how I lapped it true and checked it for squareness.

here is a link to my Youtube playlist of more workshop videos.

https://www.youtube.com/playlist?lis...O1hdmUIYO28Def

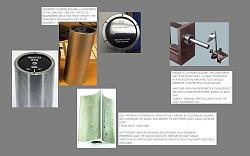

I had an old aluminium bearing housing in the scrap box which had a bore of 50 mm and the tailstock cylinder was 54 mm so I made a lap by boring out the housing and then splitting it with a bandsaw. I added a couple of clamping screws for adjustment during lapping.

Click for full size.

I had machined the bore for a nice slip fit on the cylinder, but for the initial lapping I spread the diameter a little so that I could charge it with the lapping grit and some thin oil. I worked the lapping over the areas which were the largest. The cylinder varied in diameter by only 2 tenths of a thou. prior to lapping. Pretty good but I like perfection where possible.

Lapping.

After lapping I could detect no difference in diameter over its working length. So that left the squareness to the base to be checked.

I suggest watching the video for more details. Please like and share it and subscribe to my video channel if you have not already done so.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks